In the continuous innovation process of automotive lighting systems, 26W automotive single-beam LED replacement bulbs have gradually become the preferred choice of many car owners to improve vehicle lighting effects due to their high efficiency, energy saving and high brightness. However, inside this small bulb, a "battle" about heat control is quietly taking place. As a core element, heat dissipation is like an invisible but powerful hand, tightly controlling the lighting effect and service life of the bulb.

Since its advent, LED (light-emitting diode) technology has been known for its luminous efficiency. Compared with traditional halogen bulbs, LED bulbs can convert more electrical energy into light energy, reducing energy waste in the conversion process. However, this efficient conversion process is not without cost. LED chips will generate considerable heat when working. For 26W automotive single-beam LED replacement bulbs, their power determines the working intensity of the chip, which in turn generates more heat. If this heat cannot be dissipated in a timely and effective manner, it will quickly accumulate inside the bulb.

When the temperature around the chip rises, the first thing affected is its luminous efficiency. The light-emitting principle of LED chips is based on the recombination of internal electrons and holes, and this process is extremely sensitive to temperature. The increase in temperature will reduce the recombination efficiency of electrons and holes, and a large amount of energy will no longer be released in the form of photons, but will be converted into more heat, forming a vicious cycle. The light emitted by the bulb that originally provided clear and bright lighting to the driver will become dim, the lighting range will be reduced, and the uniformity of the light will be poor. When driving at night, this will not only affect the driver's judgment of the road conditions ahead and increase the risk of accidents, but may also cause the driver to feel fatigued due to poor vision, further endangering driving safety.

In addition to the direct impact on the current lighting effect, the high temperature environment will also seriously damage the long-term stability of the LED chip and greatly shorten the service life of the bulb. Various materials inside the LED chip, such as semiconductor materials, packaging materials, etc., will undergo physical and chemical changes at high temperatures. The electrical properties of semiconductor materials will gradually degrade, causing the luminous performance of the chip to decline irreversibly. Under long-term high temperature, packaging materials may age and crack, which will not only destroy the sealing of the chip and make it more susceptible to erosion by external environmental factors, but also further affect the heat dissipation effect of the chip. The 26W automotive single-beam LED replacement bulb, which could have been used for a long time, may have a significantly reduced brightness or even completely damaged in a short period of time due to poor heat dissipation, which undoubtedly increases the owner's use cost and the frequency of bulb replacement.

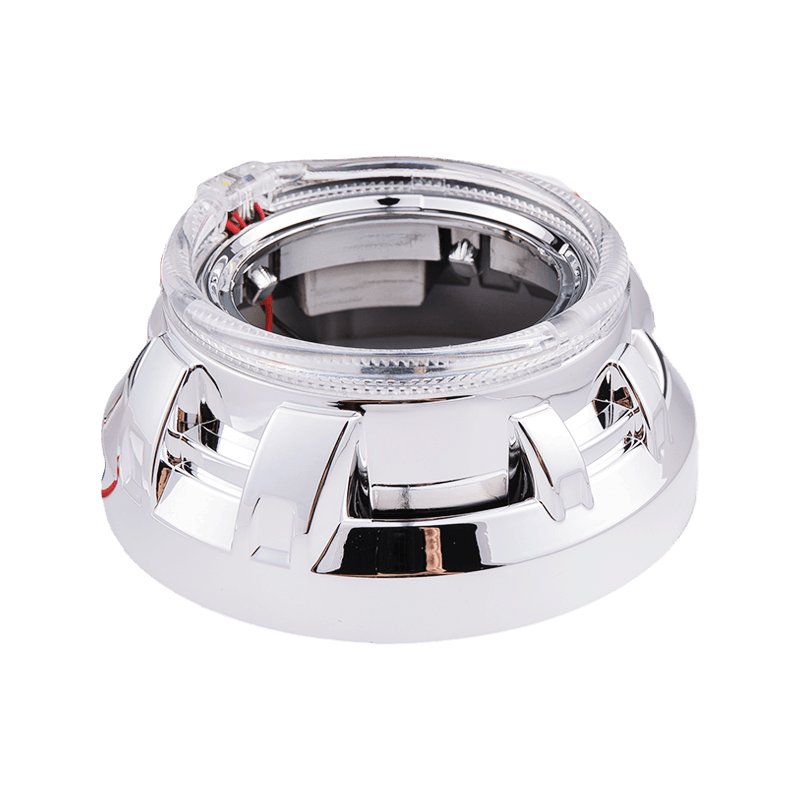

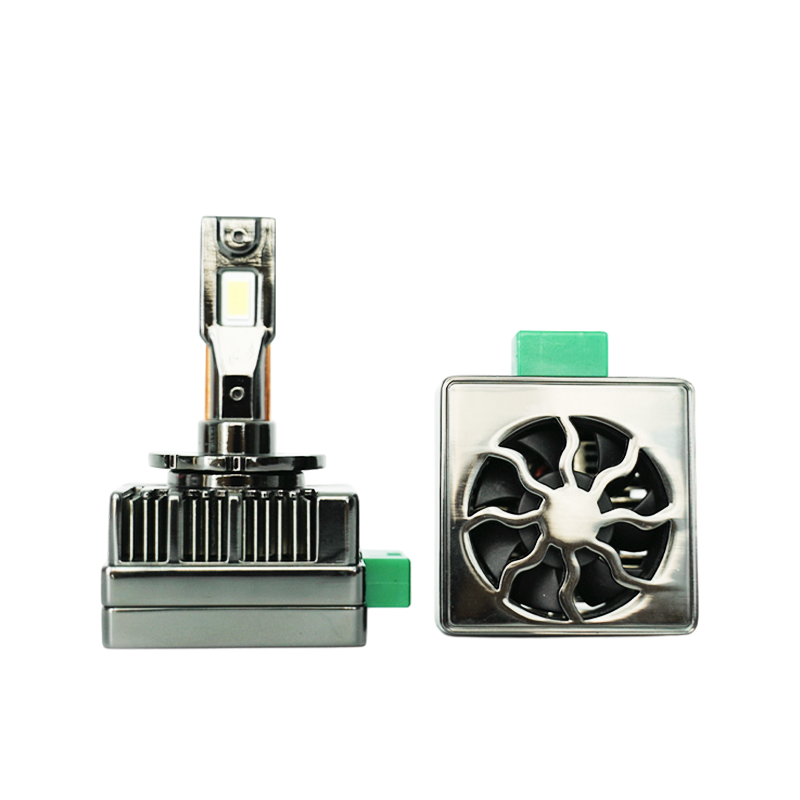

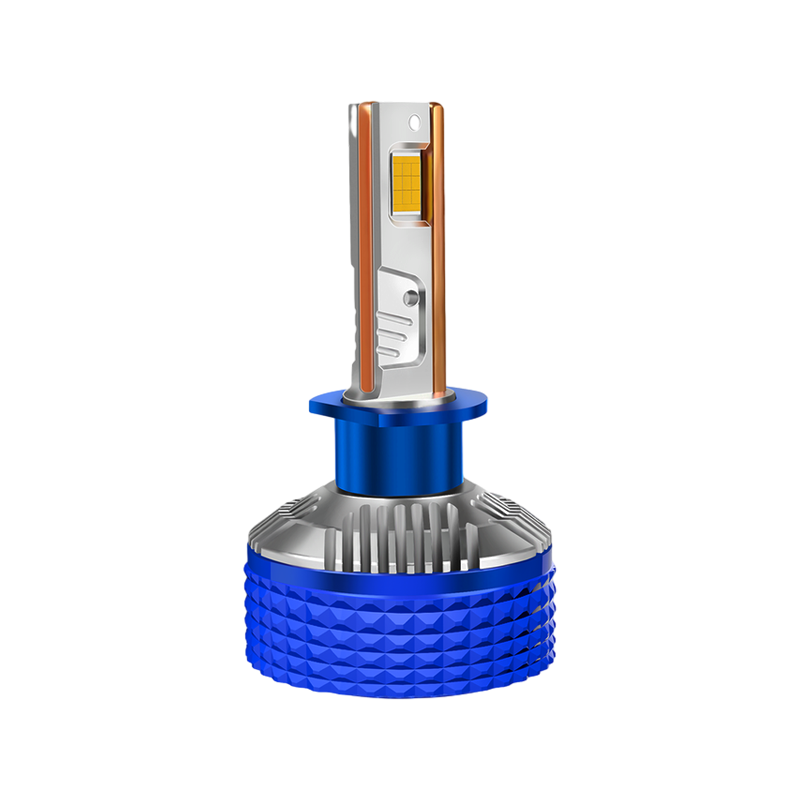

In order to cope with the key challenge of heat dissipation, the 26W automotive single-beam LED replacement bulb adopts a variety of advanced heat dissipation technologies in design. From the perspective of heat dissipation path, it is mainly divided into two stages: heat conduction from chip to lamp body and heat convection and heat radiation from lamp body to surrounding environment. High thermal conductivity materials are usually used to construct a heat conduction channel between the chip and the lamp body. For example, metal materials such as copper or aluminum are used as substrates. These metals have thermal conductivity and can quickly conduct the heat generated by the chip to avoid heat accumulation in the chip. In terms of heat dissipation from the lamp body to the surrounding environment, heat dissipation fins are a common and effective design. The heat dissipation fins increase the contact area between the lamp body and the air, and use natural convection or forced convection (such as with a cooling fan) to quickly transfer heat to the surrounding air. The carefully designed heat dissipation fin structure can maximize the heat dissipation area in a limited space, optimize the air flow path, and improve the heat dissipation efficiency. Some high-end products also use special coatings on the surface of the lamp body to enhance its heat radiation ability and further assist in heat dissipation.

Heat dissipation performance plays a decisive role in the lighting effect and service life of 26W automotive single-beam LED replacement bulbs. It not only affects the safety of drivers when driving at night, but also affects the cost-effectiveness and user experience of the product. With the continuous development of automotive lighting technology, it is believed that there will be more innovations and breakthroughs in the field of heat dissipation technology, bringing more products to 26W automotive single-beam LED replacement bulbs and the entire automotive lighting market.

English

English Español

Español عربى

عربى русский

русский