In the development process of automotive lighting systems, the iteration of light source technology has always revolved around core goals such as energy efficiency improvement, performance optimization, and reliability enhancement. As one of the current mainstream lighting solutions, 30W single-beam LED headlight bulbs show significant differences in energy efficiency performance compared to traditional halogen headlights. This difference is not only reflected in the basic photoelectric conversion efficiency level, but also extends to multiple dimensions such as the actual working efficiency, energy consumption distribution, and comprehensive use cost of the entire lighting system.

Basic energy efficiency mechanism of light source and difference in light efficiency conversion

The energy efficiency of a light source essentially depends on its ability to convert electrical energy into light energy. This process involves basic physical mechanisms such as energy conversion efficiency and spectral distribution characteristics. The working principle of traditional halogen headlights is based on thermal radiation luminescence, which heats the tungsten filament to a high temperature state (usually up to 2500-3000K) through electric current, so that the tungsten filament emits a continuous spectrum. However, only a small amount of electrical energy (about 5% - 10%) is converted into visible light during this process, and most of the remaining energy is dissipated in the form of infrared radiation (heat energy). This high heat loss characteristic makes the luminous efficacy (luminous flux produced per unit power) of halogen headlights generally low, generally in the range of 15 - 25 lm/W.

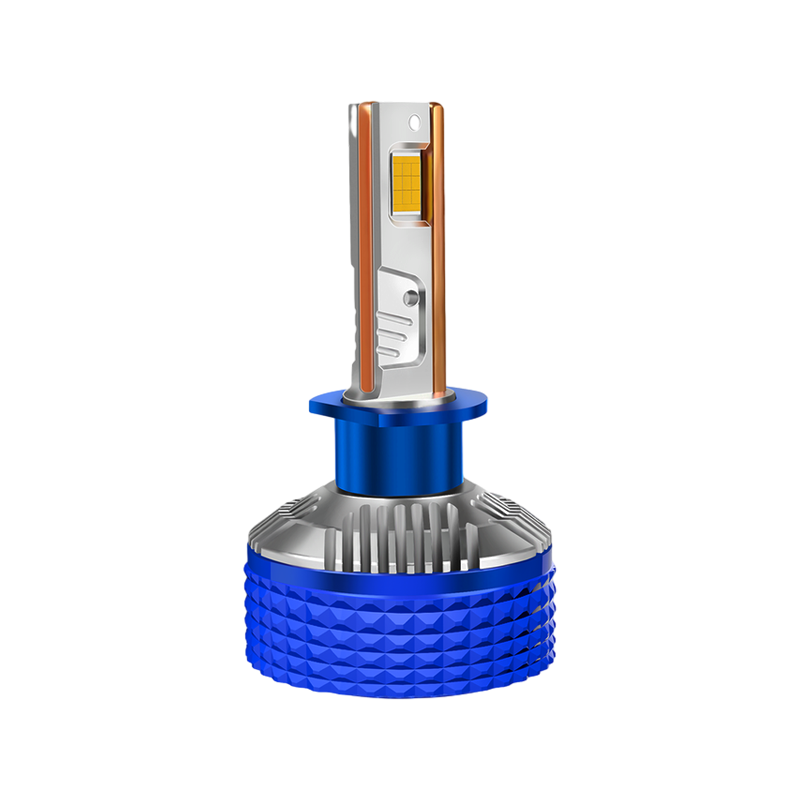

The 30W single-beam LED headlight bulb adopts a semiconductor light-emitting mechanism, the core of which is the electroluminescent effect of the PN junction. When current passes through the semiconductor material, electrons and holes recombine to release energy and generate photons. The energy conversion of this process is more direct, without the intermediate link of thermal radiation. The photoelectric conversion efficiency of modern LED chips can reach 30% - 40%, and the corresponding luminous efficacy is generally between 80 - 120 lm/W. Taking 30W power as an example, a high-quality LED headlight bulb can produce a luminous flux of 2400-3600 lm, while a halogen headlight of the same power can only output a luminous flux of 450-750 lm. This significant difference in light conversion efficiency fundamentally determines the hierarchical gap between the two in terms of energy efficiency performance.

Energy consumption composition and energy efficiency impact of thermal management system

The actual energy efficiency performance of the light source is not only determined by the light efficiency of the light source itself, but also by the energy consumption distribution and thermal management mechanism of the entire lighting system. Due to the extremely high heat loss of traditional halogen headlights, a large amount of heat energy generated during operation needs to be dissipated through the natural heat dissipation of the lamp housing. Although the thermal management structure of halogen lamps is relatively simple, this high heat generation characteristic actually forms a hidden energy efficiency loss - especially when the vehicle air conditioning system is running, the heat emitted by the lamp may increase the load of the air conditioning in the car, indirectly leading to an increase in the energy consumption of the entire vehicle. In addition, the filament of the halogen lamp will gradually sublimate in a high temperature environment, and tungsten atoms will be deposited on the inner wall of the bulb, resulting in a decrease in light transmittance. The light decay phenomenon will intensify with the extension of the use time, which will also reduce its actual energy efficiency in long-term use.

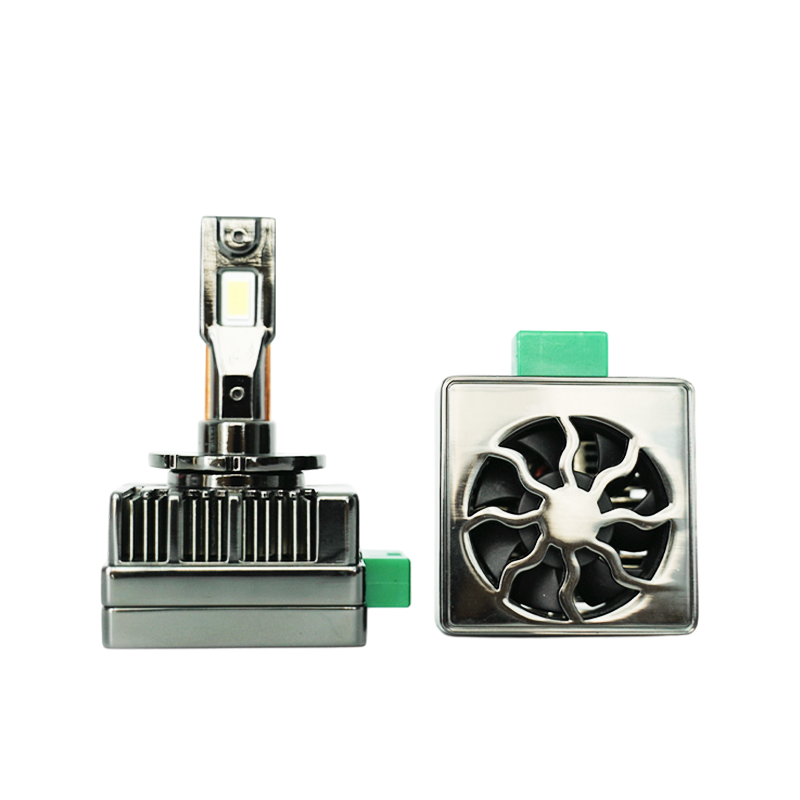

Although the photoelectric conversion efficiency of the 30W single-beam LED headlight bulb is high, some energy is still released in the form of heat, so a matching thermal management system is required to maintain the working temperature of the chip. Modern LED headlights usually use a composite heat dissipation structure composed of heat sinks, thermal conductive silicone and fans (some high-end products). Although the thermal management system itself consumes a small amount of electricity (for example, the power consumption of the fan is usually around 1-3W), the efficient heat dissipation design can control the temperature of the LED chip in the ideal working range of 60-80℃ to avoid light efficiency attenuation caused by high temperature. Research data shows that under reasonable thermal management conditions, the light decay rate of LED headlights after 3000 hours of operation is usually less than 10%, while the light decay rate of halogen lamps can reach more than 30% after the same use time. This long-term light efficiency stability enables LED headlights to maintain more consistent energy efficiency performance throughout their life cycle, avoiding the actual lighting effect decline and potential energy waste caused by light decay.

Differences in energy efficiency performance in actual use scenarios

The actual energy efficiency performance of vehicle lighting systems needs to be evaluated in combination with different use scenarios, because the working state of the light source under different working conditions will directly affect its energy consumption level. Traditional halogen headlights can quickly reach full light output during cold start, which makes them convenient in short-term use scenarios. However, due to their low light efficiency and high heat generation, they will continue to generate high energy consumption when used continuously for a long time (such as driving on highways at night), and the continuous increase in lamp temperature may shorten the life of the filament, further increasing the cost of use.

30W single-beam LED headlight bulbs can also quickly reach the rated luminous flux at the beginning of startup, and their response time is usually less than 0.1 seconds, which is not significantly different from halogen lamps. In scenarios with frequent start-stop and start-stop such as urban roads, the energy efficiency advantage of LED headlights is mainly reflected in low power consumption operation - even if it is turned off and then turned on again, its energy consumption fluctuation is relatively small. In long-term lighting scenarios such as highways, the energy efficiency advantage of LED headlights is more obvious: on the one hand, its high light efficiency characteristics enable 30W of power to provide lighting brightness equivalent to traditional 55W or even 70W halogen lamps, directly reducing power requirements; on the other hand, the stable thermal management system enables it to maintain stable light efficiency during long-term operation, avoiding additional energy consumption caused by power compensation.

It is worth noting that under extreme ambient temperatures, the energy efficiency performance of the two will fluctuate to varying degrees. The light efficiency of traditional halogen lamps may be slightly improved in low temperature environments (such as -20℃), but its high temperature tolerance is poor. When the ambient temperature exceeds 40℃, the filament sublimation speed is accelerated and the light decay is aggravated. The light efficiency of LED headlights is more significantly affected by ambient temperature: in low temperature environments, the forward voltage of LED chips increases, which may lead to a slight increase in power consumption, but modern drive circuits usually have temperature compensation functions, which can control power consumption fluctuations within 5%; in high temperature environments, if an efficient thermal management system can control the chip temperature within a reasonable range, the LED headlights can still maintain stable light output, but once the heat dissipation fails, the chip temperature exceeds 100°C, and the light efficiency may be greatly attenuated. Therefore, in actual energy efficiency comparisons, the environmental adaptability of LED headlights needs to be comprehensively evaluated in combination with the design level of their thermal management systems, and high-quality 30W single-beam LED headlights can usually maintain more stable energy efficiency performance within a wide temperature range.

Long-term energy efficiency economy and comprehensive use cost

Another important dimension of energy efficiency comparison is the economy in long-term use, which involves multiple factors such as energy consumption cost, maintenance cost, and replacement cycle. Assuming that the vehicle travels 20,000 kilometers per year, and the proportion of night driving accounts for 30%, the annual lighting time is about 200 hours (calculated at an average speed of 60km/h). The power of traditional halogen headlights is usually 55W, and the luminous efficiency is calculated at 20 lm/W, and the annual power consumption is 55W×200h = 11 kWh; the annual power consumption of 30W single-beam LED headlights is calculated at 100 lm/W, and the annual power consumption is 30W×200h = 6 kWh. Calculated at the residential electricity price of 0.6 yuan/kWh, LED headlights can save electricity costs (11 - 6)×0.6 = 3 yuan per year. Although the savings seem small from the perspective of electricity costs alone, the overall economic benefits are more obvious when considering other cost changes caused by energy efficiency differences.

In terms of maintenance and replacement costs, the average life of traditional halogen lamps is about 500-1000 hours. Calculated at 200 hours of use per year, they need to be replaced every 2-5 years, and the cost of each replacement is about 20-50 yuan. The theoretical life of a 30W single-beam LED headlight can reach 30,000-50,000 hours. Under normal use, it can meet the vehicle's use needs for more than 10 years, and almost no replacement is required. In addition, the decline in lighting effect caused by light decay of halogen lamps may prompt users to replace them in advance, further increasing maintenance costs. From the perspective of the entire life cycle, the replacement cost of a vehicle can be saved by using LED headlights during its service life (calculated as 10 years), which, combined with the 30 yuan saved in electricity bills, has significant advantages in comprehensive energy efficiency and economy.

Synergistic relationship between optical performance and energy efficiency

The energy efficiency of a light source is not only reflected in the energy consumption level, but the quality of its optical performance will also affect the actual lighting effect and energy utilization efficiency. Due to the limitation of the light-emitting principle, the spectral distribution of traditional halogen headlights is relatively broad, including a large amount of infrared and ultraviolet radiation, while the spectral energy distribution of the visible light part is relatively uniform, but lacks targeted spectral optimization. This full-spectrum characteristic makes the light color of halogen lamps yellowish (color temperature is about 2800-3200K). Although the penetration is good, the utilization rate of luminous flux is low, especially in the light distribution system, a large amount of light needs to be redistributed through reflection and refraction, and a certain amount of light energy loss will occur in the process.

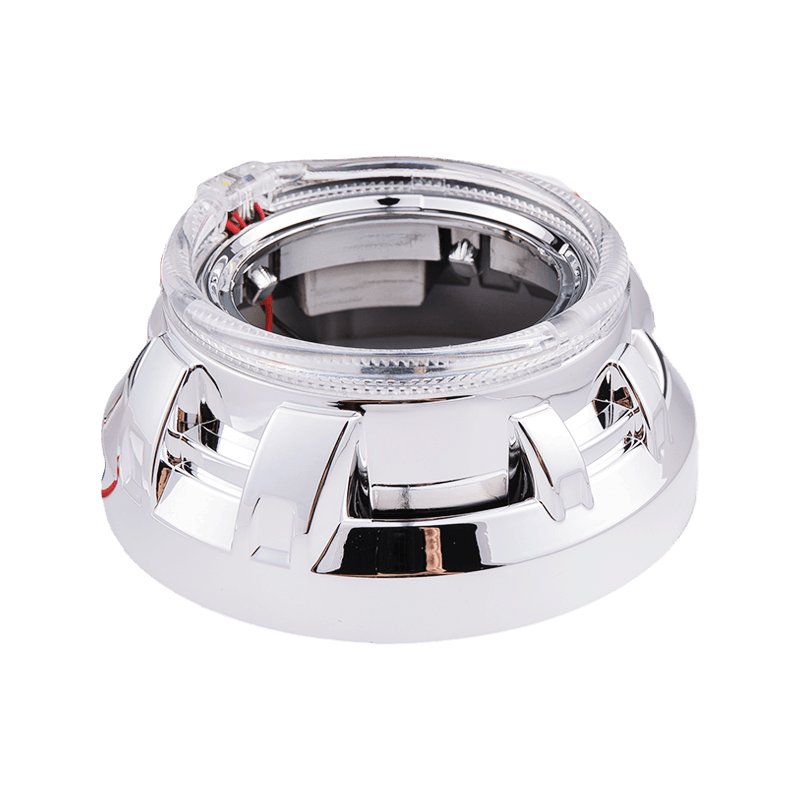

The spectral distribution of 30W single-beam LED headlight bulbs has stronger controllability. Through the selection of chip materials and phosphors, the color temperature (usually in the range of 4000-6500K) and spectral energy distribution can be precisely adjusted. For example, for road lighting needs, LED headlights can enhance the blue-green light components in the wavelength range of 450-550nm, improve the human eye's ability to identify road details, and thus achieve better lighting effects at the same luminous flux. In addition, as a point light source, the light emission direction of LED is easier to control. With the precision-designed optical lens and reflector, the light flux can be concentrated in the effective lighting area (such as the road surface and curb) to reduce invalid light scattering. Test data shows that the luminous flux utilization rate of a high-quality 30W single-beam LED headlight can reach more than 85%, while the luminous flux utilization rate of a traditional halogen headlight is usually between 60% and 70%. This optical performance advantage enables LED headlights to achieve higher effective lighting effects with lower actual power, reflecting its energy efficiency advantage from another perspective.

English

English Español

Español عربى

عربى русский

русский