In the automotive lighting system, the 3-inch round mini car LED work light is emerging with its unique advantages. Among the many key factors that determine its performance, the aluminum alloy shell plays a pivotal role. It is like a loyal guard, guarding the stable operation of the work light in all directions.

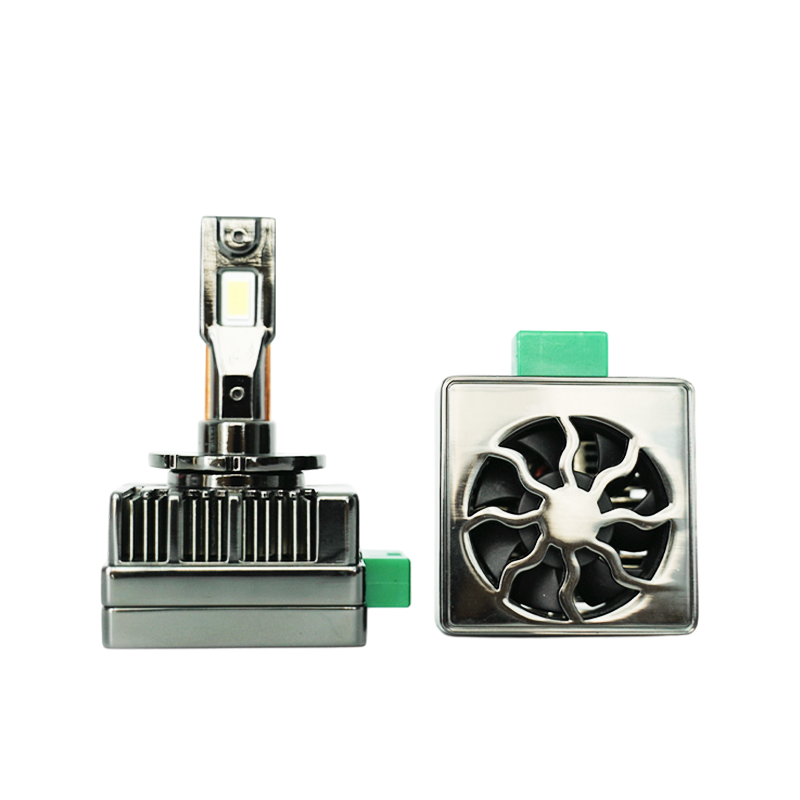

As an efficient light-emitting device, LED will inevitably generate heat in the process of converting electrical energy into light energy. For the 3-inch round mini car LED work light, due to its compact design and extremely limited internal space, the heat dissipation problem is particularly prominent. If this heat cannot be dissipated in time and effectively, the temperature of the LED lamp beads will continue to rise. Excessive temperature will have a serious impact on the luminous efficiency of the LED lamp beads, causing the brightness of the light to gradually decrease, and the originally bright light will become dim and unable to provide a clear view for the driver. High temperature will also greatly shorten the service life of the LED lamp beads. Frequent replacement of work lights will not only increase costs, but may also bring safety hazards at critical moments.

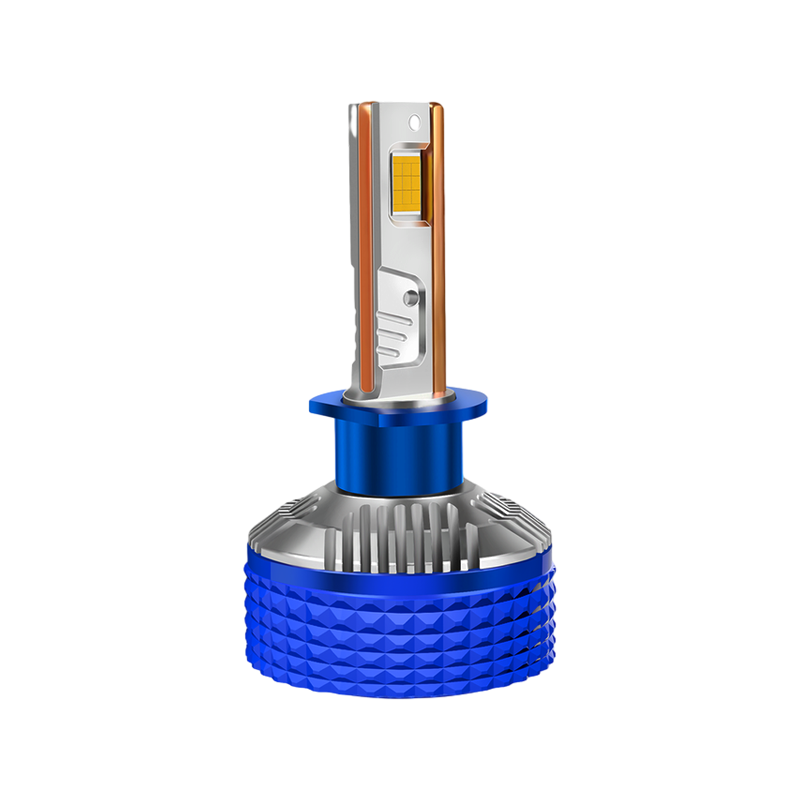

At this time, the aluminum alloy shell demonstrates its value. Aluminum alloy, with its properties, is an ideal choice for manufacturing work light housings. Aluminum alloy has a strength-to-weight ratio, is light but very strong, and can effectively resist various collisions and impacts that may be encountered during vehicle driving. In complex driving environments, whether it is the scratches of branches and splashes of stones during off-road driving, or the occasional small collisions during daily driving, the aluminum alloy housing can provide reliable physical protection for the internal precision LED lamp beads and circuit systems with its solid texture to prevent them from being damaged, thereby ensuring the normal operation of the work light.

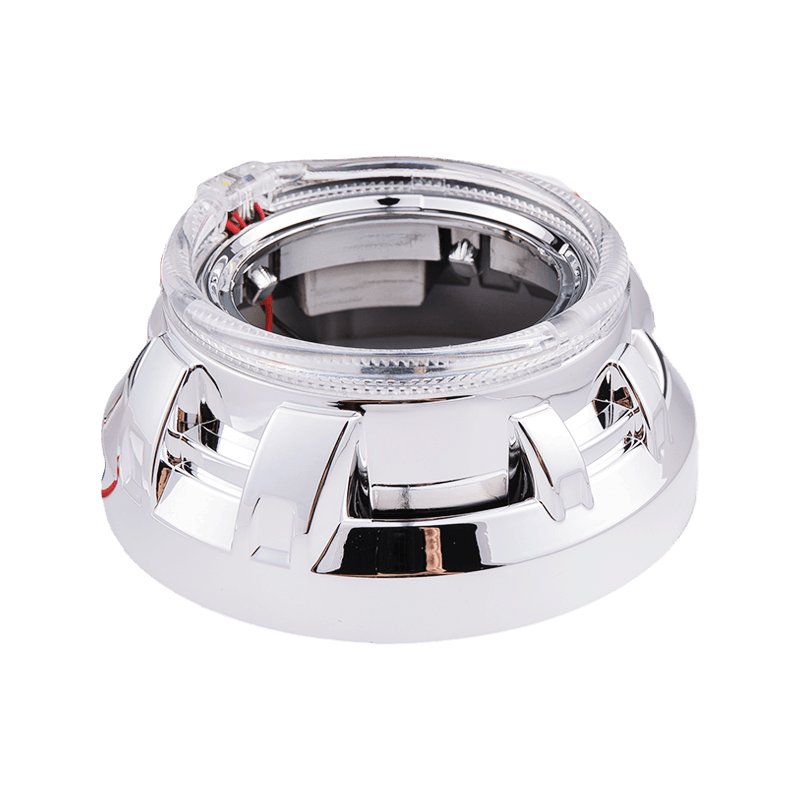

The performance of the aluminum alloy housing in heat dissipation is even more remarkable. The surface is distributed with carefully designed large-area heat dissipation fins, which are like open wings, greatly increasing the contact area between the housing and the air. When the LED lamp generates heat, the heat will be quickly transferred to the aluminum alloy housing. Because aluminum alloy has good thermal conductivity, the heat can quickly spread in the housing and be transferred to the surrounding air through the heat dissipation fins. This process is like spreading the hot charcoal fire evenly to accelerate the dissipation of heat. Through this efficient heat dissipation method, the aluminum alloy shell can quickly take away the heat generated by the LED lamp beads, so that the lamp beads are always in a suitable working temperature range. In this way, the LED lamp beads can stably maintain high luminous efficiency and continue to provide drivers with bright and stable lighting. Whether driving on a country road in the dark night or in complex off-road conditions, drivers can have a clear field of vision and ensure driving safety.

In addition, aluminum alloy materials also have good corrosion resistance. Cars are exposed to various environments for a long time and may be eroded by rain, dust, salt, etc. The aluminum alloy shell can effectively resist the erosion of these external factors and will not rust or corrode as easily as some ordinary metal materials. This not only extends the overall service life of the work light, but also always maintains its good heat dissipation performance. Because once the shell is corroded, its heat conduction efficiency will be reduced, which will affect the heat dissipation effect.

The aluminum alloy shell of the 3-inch round mini car LED work light provides reliable protection for the product with its sturdy and durable characteristics. The excellent heat dissipation design ensures that the LED lamp beads work efficiently and stably, playing an indispensable role in improving product performance and service life, bringing drivers a better and more reliable lighting experience.

English

English Español

Español عربى

عربى русский

русский