The enduring popularity of the 3 inch round mini car LED work light in demanding sectors is not accidental. It is the direct result of intentional engineering choices aimed at overcoming harsh environmental challenges. While the brilliance of the LED chips and the clarity of the lens are immediately noticeable, it is the unassuming component that forms the light’s backbone—the housing—that often dictates its operational lifespan. Specifically, the use of rugged aluminum housing has become a benchmark for quality and durability.

The Fundamental Role of Housing in Product Integrity

Before delving into the specific advantages of aluminum, it is essential to understand the multifaceted role a housing unit plays. It is far more than a simple container; it is the first and most critical line of defense for the sensitive internal components. The primary functions of the housing in a 3 inch round mini car LED work light include:

Structural Support and Mounting Integrity: The housing provides the rigid framework that holds the LED board, wiring, and lens securely in place. It must withstand constant vibration from vehicle movement without developing fatigue cracks or loosening internal connections.

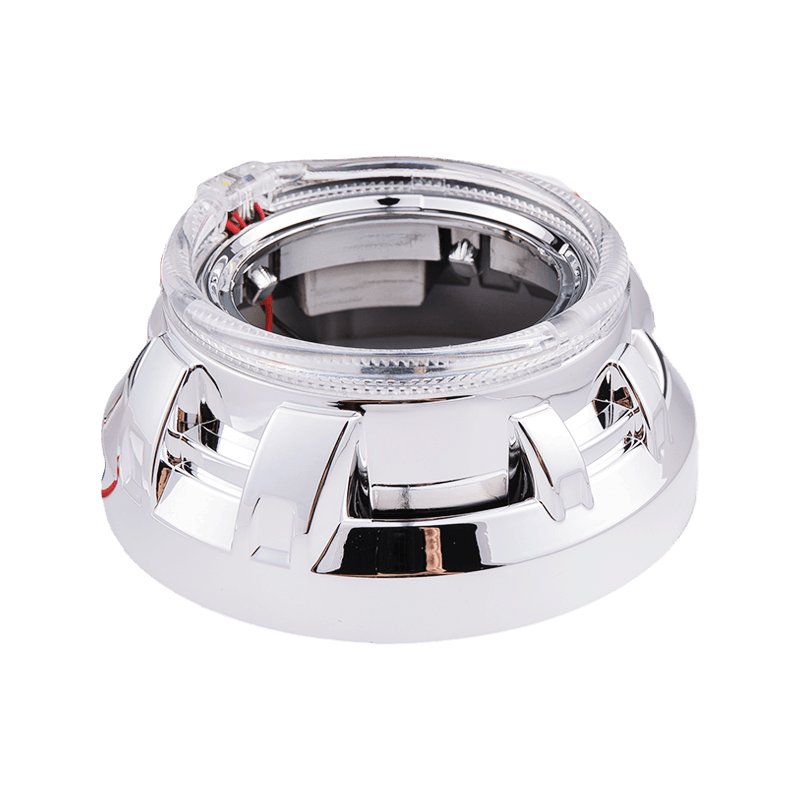

Environmental Sealing: It forms the foundation for the IP68 waterproof rating that many of these lights possess. The housing’s precise machining allows for the effective placement of gaskets and seals against the lens and mounting points, creating a hermetic barrier against moisture, dust, and debris.

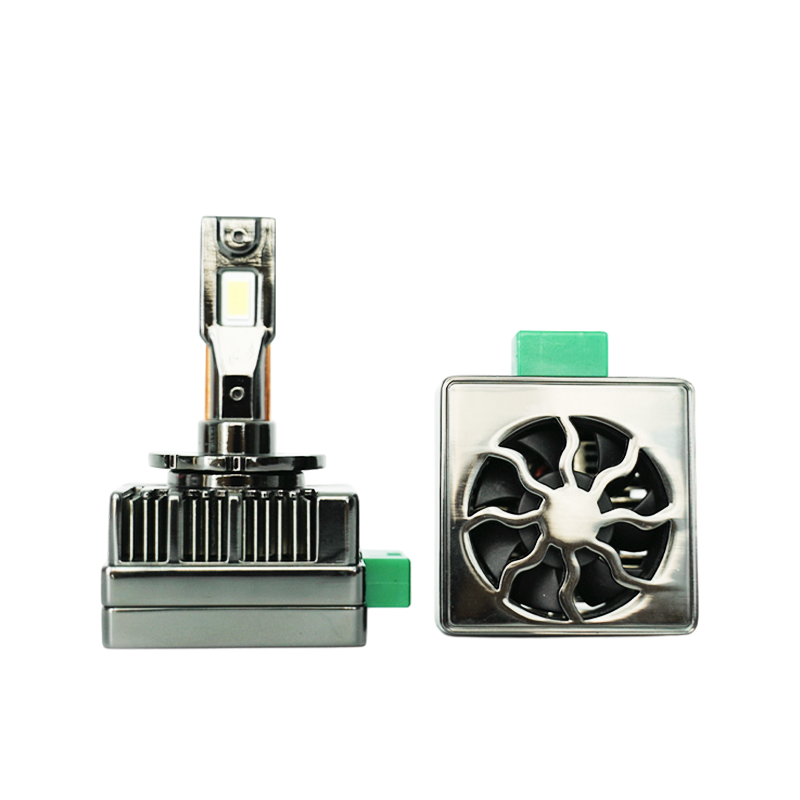

Thermal Management: This is arguably one of its most crucial, yet often overlooked, roles. LEDs generate heat at their base, and managing this heat is paramount to preventing premature failure. The housing acts as the primary heat sink, drawing thermal energy away from the LED and dissipating it into the surrounding air.

Physical Protection: The housing absorbs and deflects impacts from rocks, debris, and minor collisions, shielding the fragile LED chips and electrical components from direct damage.

A failure in any one of these functions can lead to a catastrophic failure of the entire unit. Therefore, the choice of material for this component is not a minor design decision but a fundamental determinant of the product’s service life.

Aluminum as an Engineering Material: An Analysis of Key Properties

Aluminum is selected for the construction of high-performance 3 inch round mini car LED work light housings due to a unique combination of physical and chemical properties that make it exceptionally suitable for this application. These properties work in concert to provide a level of durability that other materials, such as plastic or steel, cannot match without significant trade-offs.

Superior Thermal Conductivity and Heat Dissipation

The relationship between temperature and LED lifespan is inverse and absolute. For every significant increase in operating temperature beyond the LED’s optimal junction temperature, its lumen output decreases and its rate of degradation accelerates exponentially—a phenomenon known as Lumen Depreciation. Effective heat dissipation is, therefore, the single most important factor in ensuring the long-term brightness and functional life of an LED.

Aluminum possesses exceptionally high thermal conductivity. When the housing is designed as an integrated heat sink, it creates a highly efficient thermal pathway. Heat generated by the LED chips is rapidly transferred through the thermal compound into the housing itself. The large surface area of the rugged aluminum housing, often augmented with fins, then radiates this heat into the ambient air. This continuous cycle maintains the LED at a stable, lower operating temperature. A 3 inch round mini car LED work light with an effective aluminum heatsink housing will maintain a higher percentage of its initial lumens for thousands of hours longer than a counterpart with a poor thermal management system. This directly translates to long-lasting LED performance and consistent light output, which is a critical selling point for buyers in the off-road lighting and commercial vehicle markets.

Exceptional Corrosion Resistance in Harsh Environments

A 3 inch round mini car LED work light is routinely exposed to elements that promote rapid oxidation and corrosion. Road salt, chemical sprays, marine atmospheres, and high humidity can quickly degrade ferrous metals and certain plastics. Aluminum, however, naturally forms a thin, hard layer of aluminum oxide on its surface when exposed to oxygen. This layer is chemically inert and tightly bonded to the underlying metal, effectively passivating the surface and preventing further corrosion.

This innate corrosion resistance is a key driver of longevity. It ensures that the structural integrity of the housing remains intact over years of exposure. It prevents the formation of rust that could compromise mounting threads or seize adjustment bolts. For marine lighting and agricultural machinery applications, where exposure to water and chemicals is constant, this property is non-negotiable. Furthermore, this natural resistance can be enhanced through surface treatments such as mil-spec hard anodizing, which creates an even thicker, harder, and more durable surface layer that is highly resistant to abrasion and chemical attack.

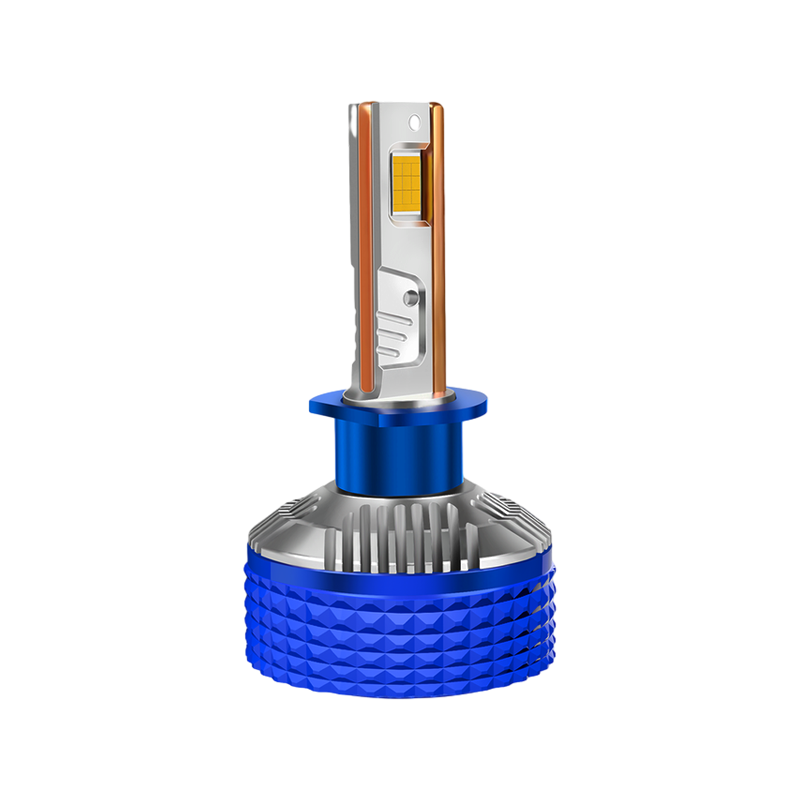

High Strength-to-Weight Ratio and Impact Resistance

The term rugged aluminum housing implies a capacity to withstand physical abuse. Aluminum alloys, particularly the 6000 series commonly used in these applications, offer an excellent balance of strength and low weight. This high strength-to-weight ratio means the housing can be designed to be robust and damage-resistant without adding excessive mass to the vehicle.

When a 3 inch round mini car LED work light is struck by road debris or impacted during off-road use, the aluminum housing acts as a sacrificial shield. Its malleability allows it to absorb and distribute the energy of an impact, often denting rather than shattering. This prevents the transfer of destructive force to the critical internal components, namely the LED board and driver, which are brittle and would fail upon a sharp impact. This impact resistance ensures that the light remains functional even after minor accidents that would permanently disable a unit with a plastic or potted housing.

Durability Against Vibration and Mechanical Stress

Vehicles are inherently high-vibration environments. On rough terrain, the constant shaking can loosen fasteners, fracture solder joints, and fatigue materials over time. The monolithic nature of a well-machined aluminum housing provides significant structural rigidity. This rigidity dampens vibration and prevents the resonant frequencies that can lead to mechanical failure.

The housing’s ability to securely hold all components in precise alignment ensures that the vibration resistance of the overall product is high. Mounting points, when integrated into the solid aluminum body, are less likely to strip or loosen compared to those embedded in plastic. This resilience against mechanical stress is a fundamental aspect of product longevity, contributing to the light’s reliability as a dependable off-road accessory or a critical safety light for work vehicles.

Comparative Analysis: Aluminum vs. Alternative Housing Materials

To fully appreciate the benefits of aluminum, it is useful to compare it with other common materials used in lower-tier lighting products. The following table illustrates the key differences:

| Material Property | Rugged Aluminum Housing | Plastic/Polymer Housing | Pressed Steel Housing |

|---|---|---|---|

| Thermal Conductivity | Very High | Very Low | Low to Moderate |

| Impact Resistance | High (Dents, does not shatter) | Variable (Can crack or shatter) | Moderate (Can dent severely) |

| Corrosion Resistance | High (with natural oxide or anodizing) | High (but can degrade with UV exposure) | Very Low (requires plating/paint) |

| Weight | Low | Very Low | High |

| Long-term Durability | Excellent | Fair to Good | Good (if corrosion is prevented) |

| Typical Cost | Higher | Lower | Moderate |

As the table demonstrates, while plastic may be a cost-effective alternative and steel offers raw strength, aluminum provides the most balanced and superior profile for ensuring the long-term performance of a 3 inch round mini car LED work light. It is the only material that excels in the critical area of thermal management while also providing excellent all-around durability.

The Synergistic Effect: How Housing Longevity Protects Internal Components

The longevity of the rugged aluminum housing is not an end in itself; its primary value lies in how it safeguards the more vulnerable and expensive internal systems of the 3 inch round mini car LED work light. This creates a synergistic effect where the durability of one component ensures the durability of the whole.

Protecting the LED Chip and Driver: By effectively dissipating heat, the housing prevents the LED driver from overheating, which is a common cause of electronic failure. Stable temperatures also ensure the LED chips do not suffer from accelerated phosphor degradation or thermal runaway, preserving both their light color and output.

Maintaining Waterproof Integrity: The dimensional stability of aluminum is crucial. Unlike some plastics that can warp under thermal cycling or UV exposure, aluminum retains its shape. This ensures that the compression on the silicone or rubber gasket remains constant, preserving the IP68 waterproof seal over thousands of hours of operation and thermal expansion/contraction cycles. A compromised seal leads to condensation, short circuits, and corrosion of internal contacts—all of which are fatal to the unit.

Ensuring Electrical Reliability: By dampening vibration, the solid housing prevents wires from fatiguing and solder joints from cracking. This maintains a stable electrical connection, preventing intermittent operation or complete failure, which is essential for lights used in safety and backup illumination.

Conclusion: A Justified Investment in Long-Term Performance

In conclusion, the use of a rugged aluminum housing in a 3 inch round mini car LED work light is a definitive engineering feature that directly and profoundly enhances its product longevity. It is not merely a marketing term but a critical design element that addresses the core challenges of thermal management, corrosion, physical impact, and vibrational stress. By ensuring stable LED operation, protecting sensitive electronics from the environment, and maintaining structural integrity under duress, the aluminum housing transforms the light from a disposable accessory into a durable, long-term investment. For wholesalers and buyers, specifying lights with this feature is a reliable indicator of a product that will deliver consistent performance, reduce failure rates, and maintain customer satisfaction over an extended service life, thereby solidifying its reputation as an essential component for demanding automotive and industrial applications.

English

English Español

Español عربى

عربى русский

русский