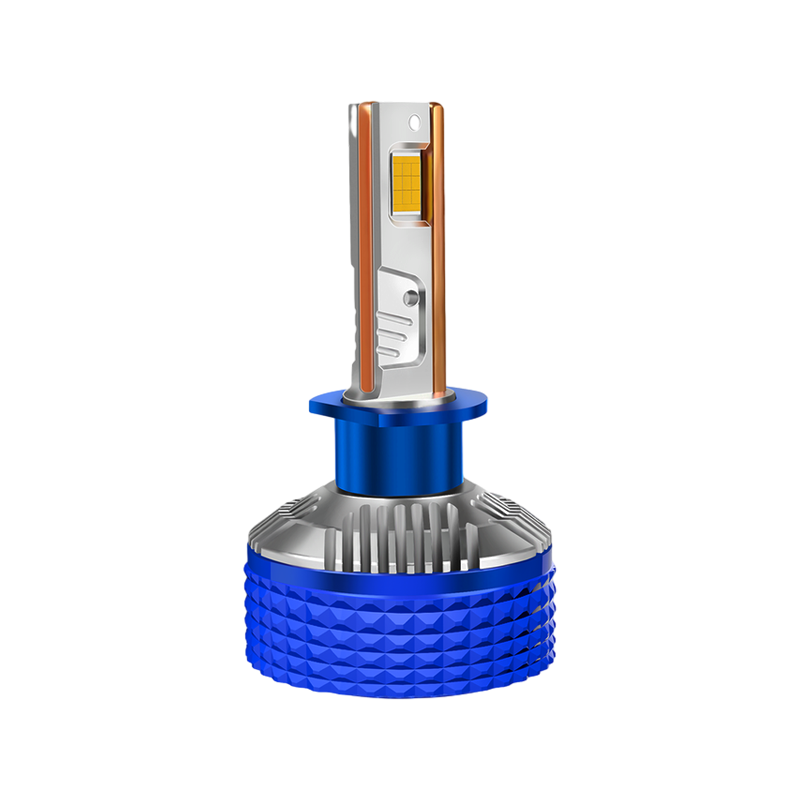

The core design concept of aluminum profile LED headlight bulbs revolves around the stringent requirements of the aviation environment. The use of high-quality aluminum profiles as the core structural material not only gives the product excellent mechanical strength, but also builds a basic framework that adapts to extreme conditions. The starting point of the design of this LED headlight bulb is not simply the pursuit of brightness. Starting from the visual needs of aviation operations, the spot shape is optimized through precise optical design to ensure uniform and glare-free lighting coverage in key areas such as runways and taxiways, which not only avoids the interference of strong light on the pilot’s vision, but also clearly presents the details of ground signs and obstacles. The introduction of aluminum profiles also realizes the integration of structure and function. Its natural metal properties enhance the product’s anti-vibration ability. For high-frequency vibrations during the operation of aircraft engines and take-off and landing, the heat generated by the LED chip during operation is quickly transferred to the outside world through a unique heat dissipation structure design, providing a basic guarantee for the long-term and stable operation of the equipment.

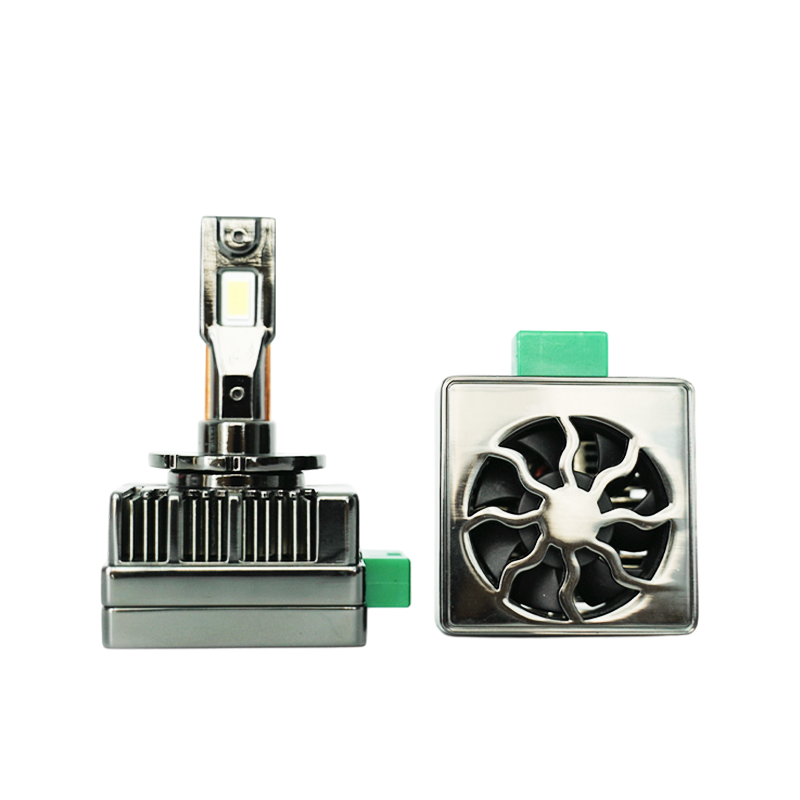

Material empowerment performance

The application of aluminum profiles in this LED headlight bulb is far more than structural support, but also a key factor in improving the overall performance of the product. From the perspective of material properties, aluminum profiles have the characteristics of low density and high strength, which not only reduces the overall weight of the bulb, facilitates installation and equipment load balance, but also can resist external force impact in complex aviation environments. In terms of heat dissipation performance, the high thermal conductivity of aluminum makes it a natural heat dissipation medium. By closely fitting with the LED chip, it forms an efficient heat dissipation channel, effectively avoiding light decay and performance degradation caused by high temperature, which is crucial for aviation lighting equipment that operates continuously for a long time. The surface of the aluminum profile can form a dense oxide layer through special treatment, which has excellent corrosion resistance and oxidation resistance, and can resist humidity changes, oil erosion and other problems that may be encountered in the aviation environment, extending the service life of the product.

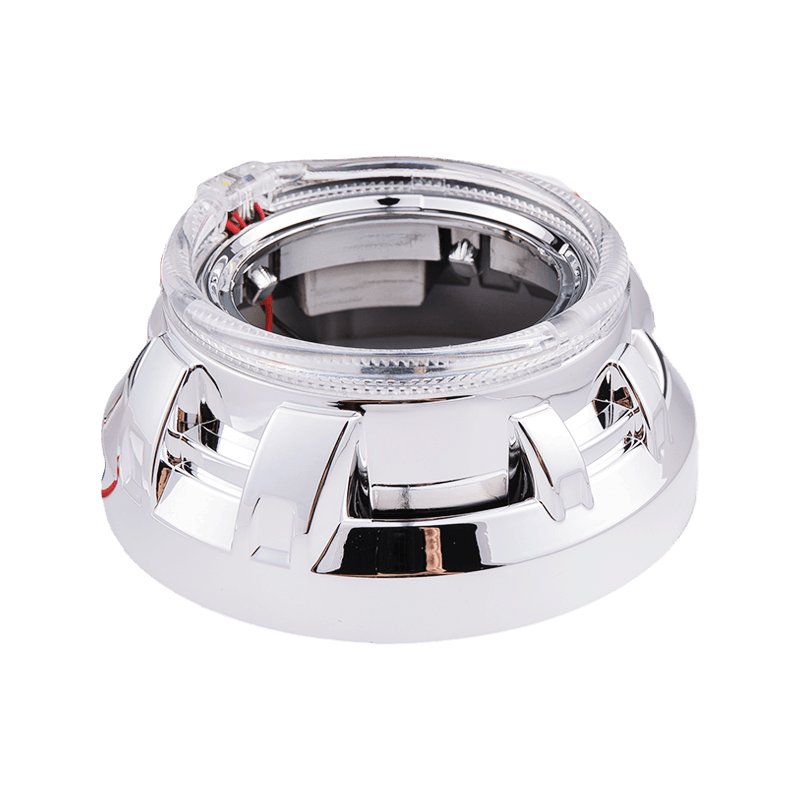

Precise control of optical performance

The core demand of aviation lighting is to improve the visibility of specific areas, and the realization of this goal depends on the precise optical design of LED headlight bulbs. Different from the floodlighting mode of ordinary lighting equipment, this product uses customized optical lenses and light source arrangements to directional guide and distribute the light to form a light spot shape that meets aviation operation standards. In runway lighting, the light spot can form a uniform light intensity distribution along the axis of the runway, ensuring that pilots have a stable visual reference during the approach and take-off and landing phases; in the taxiway area, the light spot can be adjusted according to the width of the road surface to clearly distinguish the taxiway path from the adjacent area. The product uses special anti-glare treatment to control the light refraction angle within a reasonable range, avoid direct light to the cockpit or other sensitive areas, and reduce the risk of visual fatigue and instant blindness.

Long-term and efficient practical value embodied

Long life and high energy efficiency are the significant advantages of aluminum profile LED headlight bulbs in practical terms, and are also the core support for it to become an economical and efficient aviation lighting solution. The LED light source itself has a service life far exceeding that of traditional light sources, and the heat dissipation of aluminum profiles further slows down the aging speed of the light source, reducing the downtime maintenance costs and safety risks caused by frequent replacement. In terms of energy efficiency, the inherent characteristics of LED technology make its energy consumption at the same brightness much lower than that of traditional lighting equipment. Long-term use can significantly reduce the energy consumption of aviation operations, which is in line with the modern aviation industry’s pursuit of green operations. This combination of long-term and high efficiency is not only reflected in the operation stage of the equipment, but also extends to the cost control of the entire life cycle.

The value of professional positioning

The professionalism of the aluminum profile LED headlight bulb is reflected in its deep adaptability to aviation scenes. Whether it is the daily operations of professional aviation personnel or the special needs of aviation enthusiasts, this product can meet the lighting requirements of differentiated scenes through precise performance adjustment. In professional operations, its stable light output and anti-interference ability ensure the safety of operations at night or in low visibility conditions; in non-operating scenarios, its long life and low maintenance characteristics reduce the complexity of equipment management. Compared with general lighting products, this professional positioning enables it to avoid functional redundancy, concentrate all technical advantages on serving the core needs of aviation lighting, and form a “special object for special purpose” performance advantage. The full-chain specialization from design to application not only reflects the product’s deep understanding of the aviation industry, but also makes it an ideal choice for both reliability and economy in the field of aviation lighting.

English

English Español

Español عربى

عربى русский

русский