In the field of LED headlight bulb manufacturing, the selection and application of materials play a decisive role in product performance. Aviation-grade 6063 aluminum profiles have emerged in the production of LED headlight bulbs with their unique performance advantages.

1. Material properties: physical and chemical advantages of 6063 aviation-grade aluminum profiles

l High strength-to-weight ratio and heat dissipation performance analysis

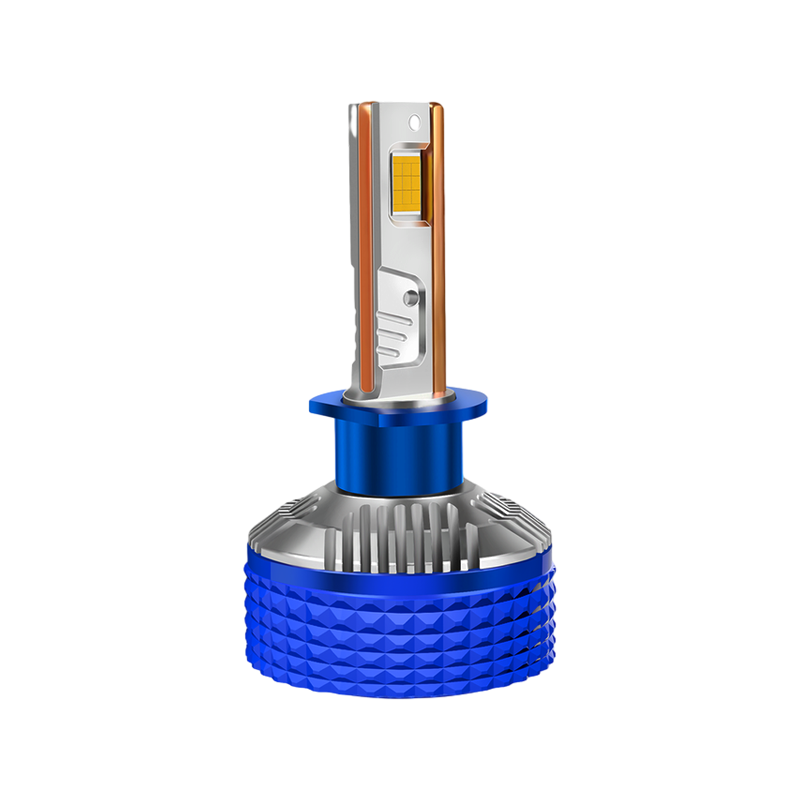

The high strength-to-weight ratio of 6063 aviation-grade aluminum is one of the key factors for its widespread use in LED headlight bulbs. Compared with other common metal materials, 6063 aluminum has high strength and is relatively light. In the aviation field, there are strict requirements on the strength and weight of materials. 6063 aluminum can meet these requirements, and this feature is also crucial in LED headlight bulbs.

LED headlights generate a lot of heat during operation. If the heat cannot be dissipated in a timely and effective manner, the temperature of the LED chip will rise, which will affect its luminous efficiency and service life. 6063 aluminum profiles have good thermal conductivity and a high thermal conductivity coefficient, which can quickly transfer the heat generated by the LED chip. In addition, its high strength-to-weight ratio allows the design of the LED headlight housing to appropriately reduce the material thickness while ensuring the structural strength, reduce the overall weight of the lamp, and facilitate installation and transportation. It also reduces the load on vehicles and other equipment.

l Anti-oxidation and surface treatment adaptability

The anti-oxidation property of 6063 aluminum profiles makes it more advantageous in the application of LED headlight bulbs. A layer of dense aluminum oxide film will naturally form on the surface of aluminum in the air, which can prevent the aluminum from further oxidation, thereby protecting the internal metal. The 6063 aluminum profile has further optimized the performance of this oxide film through a special production process, making it more resistant to oxidation.

In the use environment of LED headlights, they may be affected by complex factors such as moisture, dust, acid and alkali. Good anti-oxidation performance can ensure that the aluminum profile shell works stably for a long time without being corroded. At the same time, 6063 aluminum profiles are also very adaptable to surface treatment. It can obtain different appearance effects and protective performance through various surface treatment processes such as anodizing, electrophoretic coating, and powder spraying. For example, anodizing can enhance the wear resistance and corrosion resistance of aluminum profiles, while giving them rich colors; powder spraying can provide a thicker coating, further improve the protective ability, and can achieve various personalized appearance designs to meet the needs of different users and markets.

2. Structural design: Engineering adaptation solutions for aluminum profiles in LED headlights

l Integrated design of thermal management system

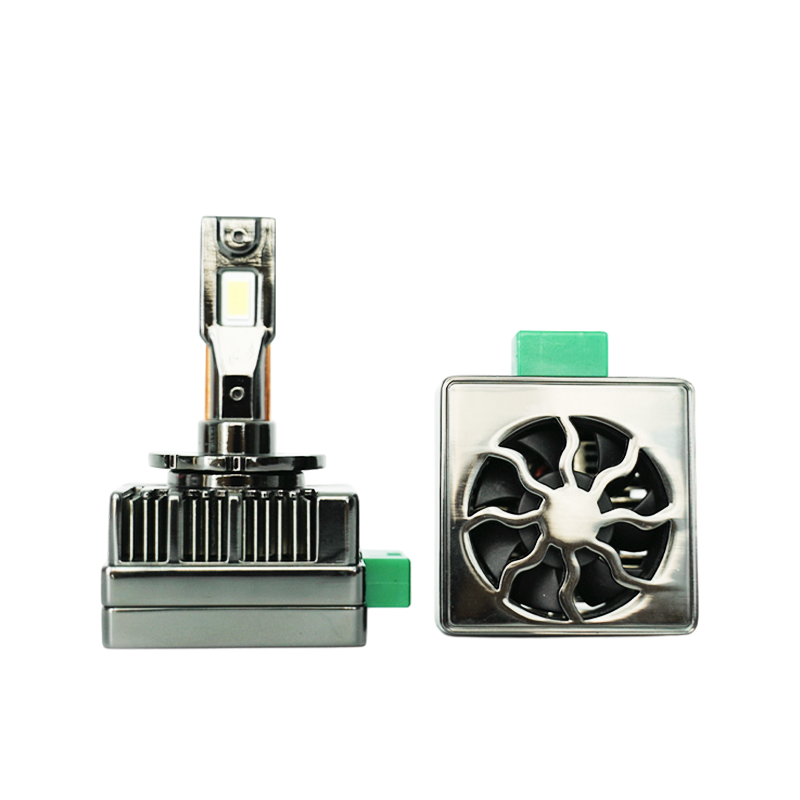

In aviation 6063 aluminum profile LED headlight bulb, the integrated design of the thermal management system is the key to ensure its normal operation. 6063 aluminum profiles have become the core material of the thermal management system due to their excellent thermal conductivity. During the design, the aluminum profiles are usually closely fitted to the LED chips to ensure that the heat can be quickly transferred to the aluminum profiles.

The heat dissipation area and heat dissipation efficiency can be increased by designing heat dissipation fins, heat dissipation holes and other structures on the aluminum profile shell. The shape, size and arrangement of the heat dissipation fins are carefully designed to optimize air flow and promote heat dissipation. At the same time, auxiliary heat dissipation equipment such as fans can be combined to further enhance the heat dissipation effect. Combining 6063 aluminum profiles with other heat dissipation materials or technologies, such as heat pipe heat dissipation and heat spreader, forms a composite thermal management system to provide a more stable and efficient heat dissipation environment for LED chips, ensuring that LED headlights can maintain good performance under long-term operation.

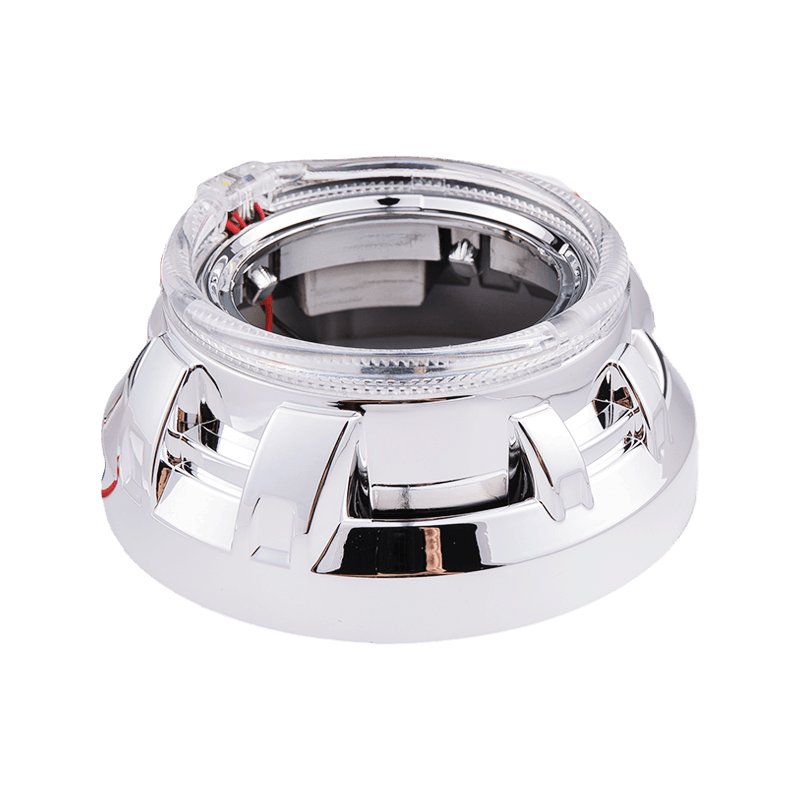

l Precision requirements for optical component fixing structures

The optical components of LED headlights play a key role in the projection and distribution of light, so the precision of their fixing structure is extremely high. 6063 aluminum profiles have good processing performance and can be used through a variety of processing processes such as extrusion, cutting, and drilling to manufacture high-precision optical component fixing structures.

During the manufacturing process, precise mold design and processing can ensure the dimensional accuracy and surface quality of the aluminum profile structure, thereby ensuring that the optical components can be accurately installed and fixed, and that the projection angle and distribution of light meet the design requirements. At the same time, the high strength of the 6063 aluminum profile can also ensure that the optical component fixing structure remains stable during long-term use, and will not deform or loosen due to factors such as vibration and collision, ensuring that the optical performance of the LED headlights remains stable.

The application of aviation-grade 6063 aluminum profiles in LED headlight bulbs has shown significant advantages in terms of material properties and structural design. With the continuous development and innovation of technology, the application of 6063 aluminum profiles in the field of LED headlights will become more extensive and in-depth, providing strong support for the performance improvement and development of LED headlight products.

English

English Español

Español عربى

عربى русский

русский