The evolution of automotive lighting has been significantly accelerated by the adoption of LED technology, offering superior illumination, efficiency, and longevity compared to traditional halogen bulbs. At the heart of a reliable and high-performance LED upgrade is a component often overlooked by the end-user but critically evaluated by wholesalers, buyers, and engineers: the housing material. The debate between aluminum and plastic housings is not merely a matter of cost or preference; it is a fundamental decision that dictates the performance, durability, and safety of the entire unit.

Introduction: The Critical Role of Housing in LED Performance

An aluminum profile LED headlight bulb is more than just a light source; it is a complex thermal-electrical system. While the quality of the LED chips and driver circuitry is paramount, their performance and lifespan are inextricably linked to the operating temperature. LEDs generate a substantial amount of heat at the semiconductor junction, and this heat must be efficiently drawn away and dissipated into the surrounding air. Failure to manage this heat leads to accelerated light decay, color shift, and a drastic reduction in operational life. The housing serves as the primary heat sink, making its material properties—specifically thermal conductivity, structural integrity, and long-term stability—the cornerstone of the product’s value proposition. Understanding the mechanical differences between aluminum and plastic is, therefore, essential for anyone involved in the specification, distribution, or installation of these components.

Fundamental Material Properties: A Comparative Overview

To comprehend the performance gap between aluminum and plastic housings, one must first examine their inherent material characteristics. These intrinsic properties directly dictate how each material will behave in the challenging environment of an automotive headlight.

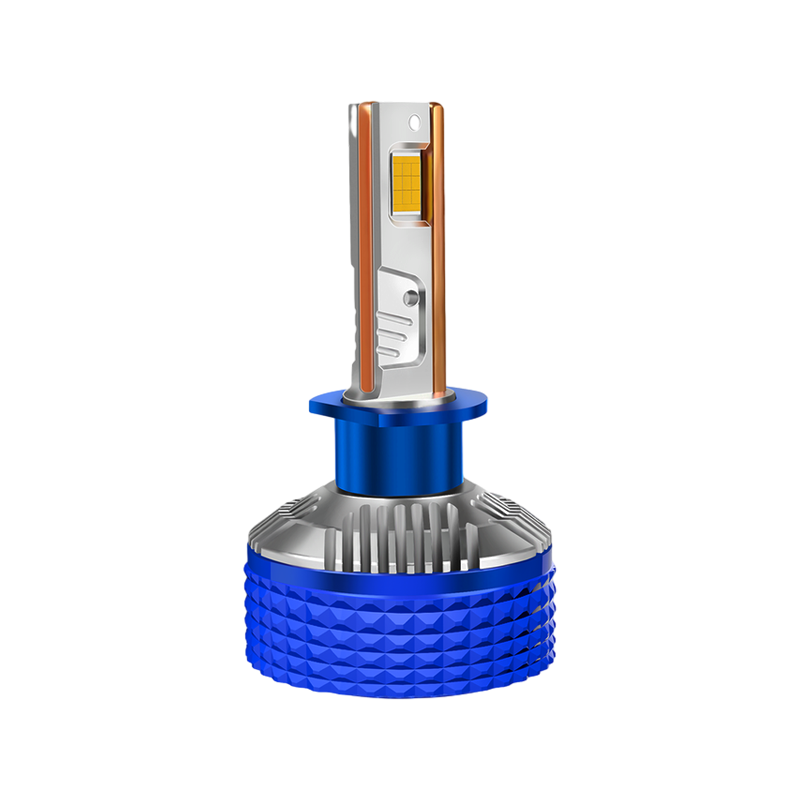

Aluminum is a metal known for its excellent thermal conductivity. This property allows heat to travel rapidly through its structure, from the heat source (the LED board) to the external fins where it can be convected away. Mechanically, aluminum offers a high strength-to-weight ratio, is inherently non-flammable, and possesses dimensional stability across a wide temperature range. This means it does not warp, soften, or creep significantly under the sustained high temperatures found in an engine bay.

Plastic, or polymer, housings are typically made from engineering grades such as PC (Polycarbonate) or PBT (Polybutylene Terephthalate), often reinforced with fibers. The primary mechanical limitation of all plastics is their very low thermal conductivity, often hundreds of times lower than that of aluminum. They act as thermal insulators, trapping heat around the LED components. While certain plastics can be formulated for high heat resistance, their maximum continuous service temperature is often lower than the potential temperature of a poorly managed LED junction. Furthermore, plastics are susceptible to UV degradation over time, which can lead to embrittlement and discoloration.

Table 1: Fundamental Material Properties Comparison

| Property | Aluminum Housing | Plastic Housing |

|---|---|---|

| Thermal Conductivity | Very High (Excellent heat dissipation) | Very Low (Acts as a thermal insulator) |

| Dimensional Stability | High (Minimal warping under heat) | Moderate to Low (Prone to creep and warping) |

| Weight | Moderate | Low |

| Max Continuous Service Temp | Very High (>200°C) | Moderate (Varies by grade, often 100-150°C) |

| UV Resistance | Excellent (Can be anodized) | Requires additives to prevent degradation |

| Flammability | Non-flammable | Can be formulated to be self-extinguishing |

Thermal Management: The Core of Performance and Longevity

The most significant mechanical difference, and the one with the most profound impact on the aluminum profile LED headlight bulb, is thermal management. This is not a minor feature but the defining factor for the product’s core promise of long life and consistent output.

An aluminum profile LED headlight bulb is designed with the housing as an integral part of the cooling solution. The aluminum housing makes direct contact with the PCB containing the LED chips. Due to its high thermal conductivity, heat is rapidly absorbed and transferred throughout the entire mass of the housing. The extensive finned design, which is mechanically feasible and effective with aluminum, maximizes the surface area exposed to air, facilitating efficient heat dissipation through convection. This process maintains the LED junction temperature within its safe operating limits, ensuring stable lumen output and preventing the accelerated failure of both the LEDs and the driver electronics.

In contrast, a plastic housing creates a thermal bottleneck. Since plastic is a poor conductor, heat generated by the LEDs becomes trapped within the enclosed space of the housing. The heat has no efficient path to escape, causing it to build up around the sensitive electronic components. This leads to an overheating LED bulb, which triggers a cascade of negative effects. The immediate consequence is thermal throttling, where the driver circuit reduces power to the LEDs to prevent catastrophic failure, resulting in a dimming light output. The long-term consequences are more severe: sustained high temperatures dramatically shorten the lifespan of the LEDs and can cause the plastic housing itself to deform, warp, or even melt over time, creating a potential safety hazard.

Structural Integrity and Durability Under Stress

Beyond heat, an automotive headlight bulb must withstand a range of mechanical stresses throughout its service life. The structural performance of the housing material is crucial for reliability.

Aluminum housings provide exceptional mechanical strength and rigidity. They are highly resistant to the vibrations encountered during normal vehicle operation and on rough road surfaces. This vibration resistance ensures that the internal components remain securely in place, maintaining the critical alignment between the LEDs and the reflectors or projectors in the headlight assembly. Proper alignment is essential for achieving the correct beam pattern and avoiding unsafe glare for oncoming drivers. The hardness and durability of aluminum also make it resistant to impact damage during handling and installation.

Plastic housings, while capable of being designed to be sturdy, are fundamentally less rigid than metal. Under continuous vibration, plastic can fatigue over time, potentially leading to cracking or a failure of the mounting points. Furthermore, the issue of heat degradation directly impacts structural integrity. If the internal temperature exceeds the plastic’s heat deflection temperature, the housing can soften and deform. This deformation can misalign the LED chips, ruining the beam pattern and compromising the effectiveness of the headlight. This risk is particularly pronounced in enclosed headlight assemblies where ambient temperatures are already elevated.

Weight and Design Considerations

The physical design and weight of the component are also influenced by the choice of housing material.

Aluminum, while denser than plastic, allows for a highly efficient design. The material’s strength enables the creation of thin yet rigid walls and complex, high-surface-area fin structures that are optimal for cooling. The weight of a well-designed aluminum profile LED headlight bulb is not typically a concern for vehicle operation, and the mass can even contribute to damping minor vibrations.

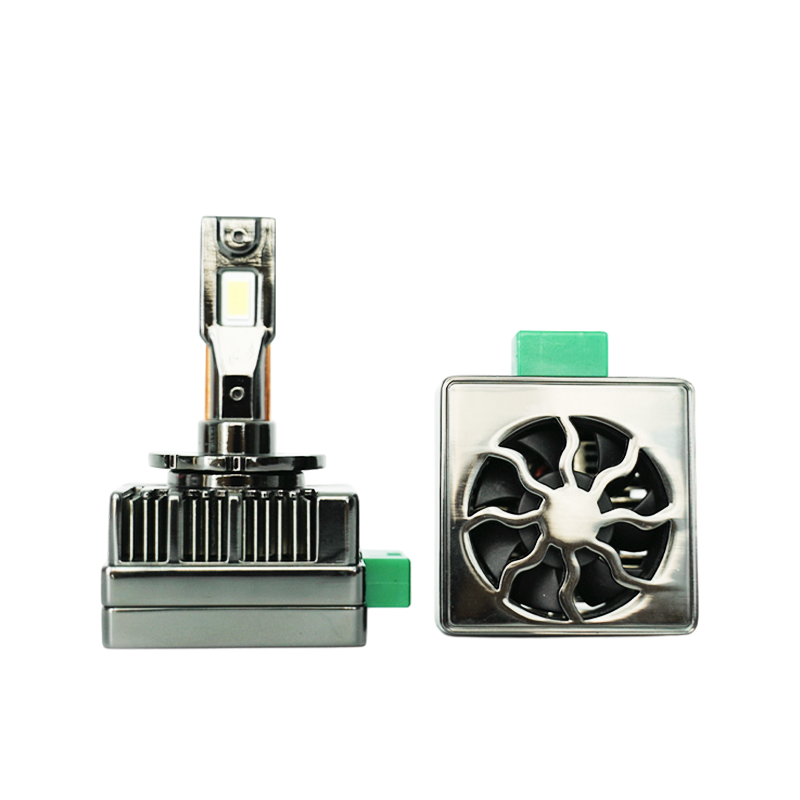

Plastic housings are notably lighter, which can be a minor advantage in shipping and handling. However, this advantage is offset by significant design limitations for cooling. To achieve any meaningful heat dissipation, plastic housings often must be made bulkier and may require the incorporation of internal metal heat sinks or active cooling systems like fans. While a fan can aid in airflow, it represents an additional point of potential failure—a moving part that can wear out or fail—and does not solve the fundamental issue of poor thermal conduction from the LED to the surrounding environment.

Long-Term Reliability and Failure Modes

The long-term value of a product is measured by its reliability and the ways in which it may eventually fail. The choice of housing material dictates the primary failure modes of an LED headlight bulb.

Products utilizing an aluminum housing typically fail gracefully, often due to the eventual wear-out of the driver electronics after many thousands of hours of operation. The LEDs themselves are kept at a stable temperature, preserving their light output and color characteristics for the vast majority of their rated life. The housing itself will remain physically intact and functional for the life of the vehicle.

The failure modes for bulbs in plastic housings are more varied and often premature. The most common issues are directly linked to heat. These include:

- Catastrophic LED Failure: The LEDs burn out quickly due to chronic overheating.

- Driver Failure: The sensitive driver circuitry is degraded by constant exposure to high temperatures.

- Physical Deformation: The housing warps, leading to beam misalignment or failure to fit securely in the headlight assembly.

- Color Shift and Light Decay: The LED output dims and changes color temperature significantly well before its expected lifespan.

This makes the longevity of LED bulbs with plastic housings inherently less predictable and generally shorter than their aluminum-housed counterparts.

Economic and Value Analysis for Wholesalers and Buyers

For wholesalers and buyers, the initial procurement cost is only one part of the total cost of ownership. A deeper value analysis must consider the long-term implications for inventory, returns, and brand reputation.

While an aluminum profile LED headlight bulb may carry a higher initial unit cost compared to a plastic-equivalent, this premium is justified by its superior performance and reliability. Investing in a product with a demonstrably lower failure rate translates into fewer customer returns, reduced warranty claims, and less logistical overhead associated with processing defective units. This builds customer trust and reinforces a reputation for supplying quality parts. For the installer or end-user, the value is clear: a one-time installation that delivers consistent, safe performance for years, without the need for premature replacement.

Conversely, the lower upfront cost of plastic-housed bulbs can be a false economy. A higher rate of premature failure leads to increased return rates, customer dissatisfaction, and potential damage to a wholesaler’s brand credibility. The costs associated with processing returns, restocking, and handling customer complaints can quickly erode the initial margin gained from purchasing the cheaper product. Furthermore, in a competitive market, the ability to offer and stand behind a demonstrably superior product is a significant competitive advantage.

Conclusion: Making an Informed Mechanical Choice

The mechanical differences between aluminum and plastic housings are not subtle; they are fundamental and have a direct causal relationship with the performance, durability, and safety of an aluminum profile LED headlight bulb. Aluminum, with its exceptional thermal conductivity and structural integrity, provides an engineered solution that actively manages the primary challenge of LED operation: heat. This results in a product that delivers on the promises of long service life, consistent light output, and reliable operation under demanding conditions.

Plastic housings, constrained by the material’s innate properties as a thermal insulator, present a compromise that ultimately jeopardizes the core functionality of the LED bulb. The risks of overheating, premature failure, and beam misalignment make them a less reliable choice for critical applications like automotive headlighting.

For wholesalers, buyers, and informed consumers, the choice is clear. Prioritizing the mechanical superiority of an aluminum housing is an investment in product quality, customer satisfaction, and long-term value. It is a decision grounded in the undeniable principles of material science and thermal dynamics, ensuring that the advanced technology of the LED is fully realized and reliably delivered.

English

English Español

Español عربى

عربى русский

русский