For wholesalers, retailers, and automotive enthusiasts navigating the rapidly evolving landscape of vehicle lighting, understanding the nuances between product categories is fundamental to making informed inventory and purchasing decisions. Among the most significant advancements in recent years is the h4/h73 inch led double light cup bifocal lens. This component represents a pinnacle of design aimed at delivering superior performance. However, a common point of confusion arises at the most basic level: the distinction between the H4 and H7 designations. While they may appear similar, especially within the same advanced housing, the differences are critical.

Understanding the Foundation: Bulb Bases and Housing Standards

Before delving into the specifics of the advanced lens technology, it is essential to grasp the fundamental nature of H4 and H7. These are not arbitrary model numbers but internationally recognized standardized codes for specific types of automotive headlight bulbs and their corresponding sockets. The core difference lies in their functional architecture and how they integrate with a vehicle’s electrical system to produce light. The advent of the h4/h73 inch led double light cup bifocal lens does not erase these foundational standards; instead, it builds upon them, often offering a unified housing that accommodates the distinct wiring and base requirements of each type. For buyers and sellers, recognizing that H4 and H7 are primarily defined by their physical and electrical interface is the first step in understanding their application and market segmentation. This knowledge is crucial for ensuring correct vehicle compatibility and managing inventory effectively.

The H4 Standard: A Legacy of Dual-Filament Design

The H4 bulb standard has been a mainstay in the automotive industry for decades, particularly known for its application in vehicles that use a single reflector or lens for both low and high beam functions. The defining characteristic of an H4 bulb is its dual-filament design. Within a single glass envelope, two separate filaments are positioned at precise focal points. When the driver switches from low beam to high beam, electrical power is redirected from one filament to the other. This change in the light source’s position within the reflector or lens assembly alters the beam pattern, creating the wider, shorter, and asymmetrically dipped low beam and the longer, more focused high beam. The base of an H4 bulb typically features three lugs arranged in an uneven pattern, a design that ensures it can only be inserted into the socket in one correct orientation. This is critical for maintaining the proper alignment of the beam pattern, especially the vital low-beam cut-off. In the context of a modern h4/h73 inch led double light cup bifocal lens, this traditional dual-filament concept is translated into a sophisticated double light cup system, where two distinct LED chips or arrays, often on a single board, mimic the function of the two filaments, all housed within the innovative bifocal lens.

The H7 Standard: The Single-Filament Specialist

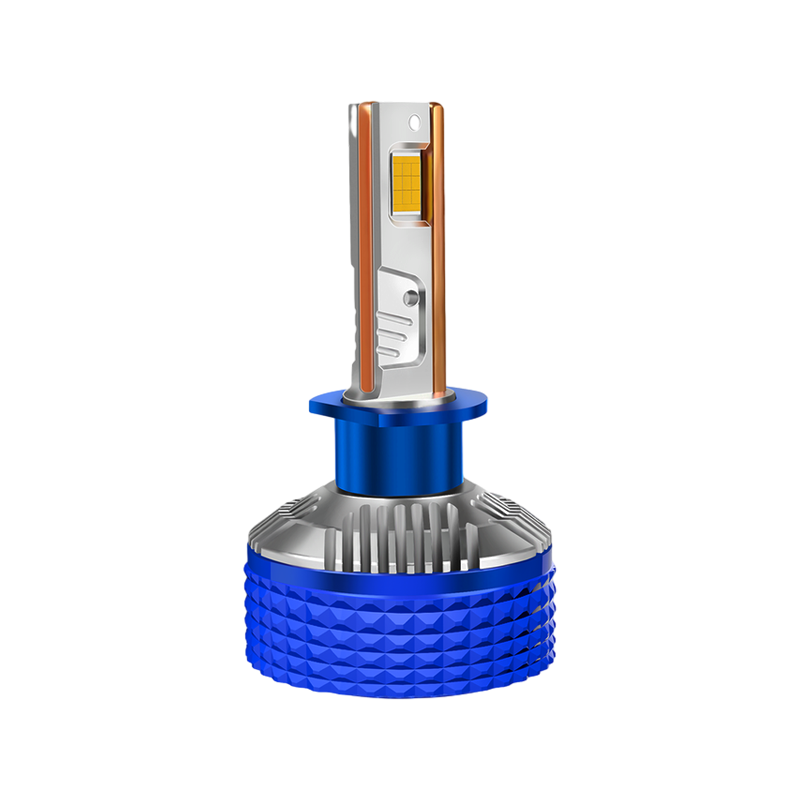

In contrast to the H4, the H7 standard represents a more modern approach that emphasizes specialization and often, higher potential output per filament. An H7 bulb is a single-filament component. This means that vehicles designed for H7 bulbs require separate bulb units for low beam and high beam functions. A typical vehicle headlamp assembly using H7 will contain two bulbs per side—one for low beam and one for high beam. This design allows each bulb and its corresponding reflector segment to be optimized for a single, specific purpose. The filament in an H7 bulb is often engineered for exceptional precision and can frequently handle higher wattages, leading to a potential for greater raw lumen output compared to a single filament in an H4 bulb. The base of an H7 bulb is distinct from H4, usually featuring a simple, symmetric clip-in mechanism with a keyed plastic base. The move towards H7 systems in original equipment manufacturer (OEM) designs has been driven by the pursuit of more precise and powerful light patterns. When integrated into an h4/h73 inch led double light cup bifocal lens, the H7 version is designed to function as a dedicated low-beam or high-beam unit, with its single light cup and LED array perfectly tuned for that specific role.

A Comparative Analysis: H4 vs. H7 in a Modern LED Context

When both standards are implemented within the same high-performance housing, such as the h4/h73 inch led double light cup bifocal lens, the core differences persist, shaping their respective applications, advantages, and limitations. The following table provides a clear, side-by-side comparison of these key attributes.

| Feature | H4 (Dual-Function) | H7 (Single-Function) |

|---|---|---|

| Core Function | Integrates low and high beam in a single unit. | Dedicated to either low beam or high beam. |

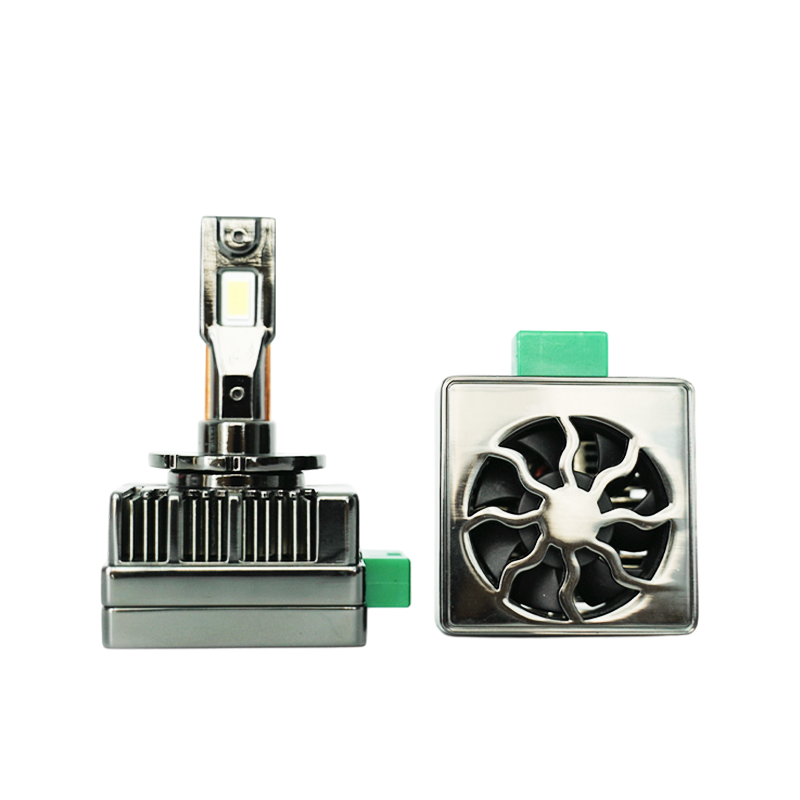

| Internal Design | Double light cup system with two LED arrays. | Single light cup with one focused LED array. |

| Vehicle System Requirement | One bulb per side handles all functions. | Two bulbs per side are typically required. |

| Beam Pattern Optimization | A balance between two functions; a compromise. | Highly optimized for a single, specific function. |

| Wiring & Installation | Requires a more complex 3-pin connector. | Simpler 2-pin connector for each bulb. |

| Common Market Application | Popular for aftermarket upgrades, motorcycles, and specific regional vehicles. | Widely used in modern OEM passenger and commercial vehicles. |

Functional Distinctions and System Integration

The most significant practical difference lies in how the H4 and H7 versions of the h4/h73 inch led double light cup bifocal lens integrate into a vehicle’s existing headlight system. An H4 unit is a self-contained all-in-one solution. It is engineered to connect directly to the vehicle’s original H4 socket and wiring harness. When installed, a single h4/h73 inch led double light cup bifocal lens unit on each side of the vehicle manages the complete headlight functionality. The switching between the low and high beam is handled internally by the unit’s driver or via the vehicle’s standard H4 power switching. This makes the H4 version an exceptionally popular plug and play led headlight upgrade for vehicles originally equipped with halogen H4 bulbs, offering a significant performance improvement with minimal modification.

Conversely, the H7 version is a specialist component. A vehicle designed for H7 bulbs will have separate sockets for the low beam and high beam. Therefore, to fully convert such a vehicle, one would need to purchase two h4/h73 inch led double light cup bifocal lens units per side: one set specified for low beam and another set specified for high beam. The wiring remains simple, as each unit plugs into its dedicated existing socket. This approach allows for unparalleled optimization. The low-beam unit can have its bifocal lens and light cup perfectly calibrated to create a sharp, clear cut-off line to prevent glare for oncoming traffic, while the high-beam unit can be designed to project light as far and wide as possible without the constraints of a low-beam pattern.

Performance and Beam Pattern Considerations

From a performance perspective, the debate often centers on specialization versus consolidation. The H4 version, with its dual light cups, performs admirably in both low and high beam scenarios. Modern designs have minimized the historical performance gap, and a high-quality h4/h73 inch led double light cup bifocal lens will produce a excellent, compliant beam pattern for both functions. However, by its very nature, it represents an engineering compromise. The lens and reflector geometry must work effectively for two different light source positions.

The H7-based system, by dedicating a full h4/h73 inch led double light cup bifocal lens to a single task, has the potential to achieve a higher degree of perfection in that specific task. The single light cup can be positioned at the absolute optimal focal point for its designated function, and the bifocal lens can be sculpted with a singular purpose. For professionals and enthusiasts seeking the absolute best possible low-beam performance with a flawless cutoff line and minimal scatter, or the most powerful and far-reaching high beam, the H7 route in a dedicated system is often considered the superior approach. This makes understanding the beam pattern specifications for each variant a critical task for buyers.

The Unifying Technology: The Role of the Double Light Cup and Bifocal Lens

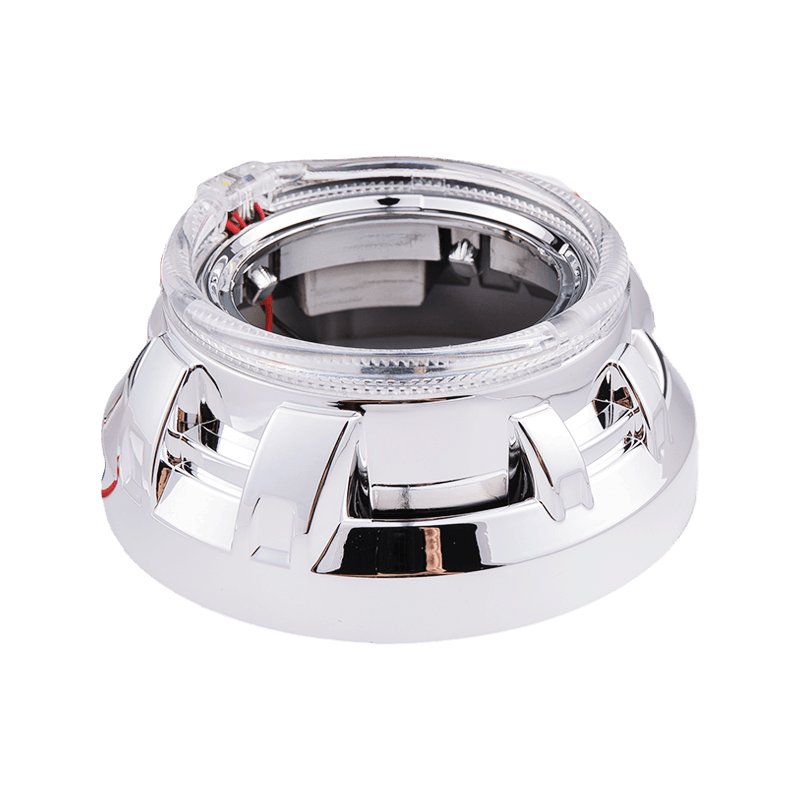

It is crucial to recognize that the advanced performance of both the H4 and H7 variants is largely enabled by the shared core technology: the double light cup and the bifocal lens. This is what separates these modern units from older, often non-compliant, LED upgrades. The double light cup is the physical mechanism that replaces the filaments in a halogen bulb. In an H4 unit, there are two distinct cups, one for low beam and one for high beam, each containing its own set of LED chips. In an H7 unit, there is a single, precision-engineered light cup. The purpose of the cup is to gather and pre-focus the raw light from the LEDs, directing it precisely towards the lens in a controlled manner. This is the first and most critical step in preventing stray light and glare.

The bifocal lens is the second stage of this precision optical system. Unlike a simple clear or frosted lens, a bifocal lens has a complex surface with specifically designed micro-patterns or facets. These facets act like a series of tiny prisms and lenses, taking the pre-focused light from the light cup and sculpting it into a regulated beam pattern. For low beams, this means creating the sharp cutoff line that rises on the curb side to illuminate road signs and pedestrians while dipping on the driver’s side to avoid blinding oncoming traffic. The accuracy of this lens is what determines whether an LED upgrade is truly street-legal and safe, making the h4/h73 inch led double light cup bifocal lens a key term for buyers seeking compliant products. The integration of these two components ensures that the intense light from the LEDs is not just emitted, but is properly controlled and distributed, which is the hallmark of a quality lighting product.

Compatibility and Inventory Management for Wholesalers

For wholesalers and distributors, the H4 vs. H7 distinction has direct implications for inventory strategy and market targeting. Understanding the vehicle parc in your target market is essential. Regions or vehicle segments with a high prevalence of older models, motorcycles, or specific types of commercial vehicles might have a stronger demand for the H4 variant of the h4/h73 inch led double light cup bifocal lens. These markets are driven by the desire for a simple, effective, and direct plug and play upgrade.

Conversely, markets focused on newer passenger cars, performance vehicles, and European models will likely see much higher demand for the H7 variant. It is important to stock both the low-beam and high-beam specific versions of the H7 unit to cater to this demand. Furthermore, canbus error free functionality is a critical search term and product feature to highlight. Modern vehicles with complex computer systems (Canbus) will often interpret the low power draw of LED bulbs as a fault, triggering warning messages on the dashboard. Units designed with built-in load resistors or compatible drivers to prevent this are essential for a seamless customer experience and reduced return rates. Advertising your h4/h73 inch led double light cup bifocal lens products as canbus ready or error free is a significant competitive advantage.

Conclusion: Making the Informed Choice for Your Business

In summary, the difference between H4 and H7 within a h4/h73 inch led double light cup bifocal lens lineup is not about one being universally superior to the other. Rather, it is about application, vehicle compatibility, and performance priorities. The H4 variant stands as a versatile, all-in-one solution ideal for direct replacement in single-bulb systems, prized for its simplicity and comprehensive functionality. The H7 variant embodies a specialized, performance-oriented approach, requiring a paired setup but offering the potential for optimized beam patterns in vehicles designed for separate low and high beam bulbs.

For professionals in the automotive lighting supply chain, a deep understanding of this distinction is invaluable. It allows for accurate customer consultation, efficient inventory planning, and targeted marketing. By recognizing that the advanced h4/h73 inch led double light cup bifocal lens platform serves two distinct but equally important market needs, you can ensure that you are providing the correct, high-performance lighting solution for every customer and vehicle application. The future of automotive lighting is rooted in such precise optical engineering, and clarity on these fundamental standards is the first step toward capitalizing on that future.

English

English Español

Español عربى

عربى русский

русский