Introduction: The Central Role of Thermal Management in LED Performance

The advent of 26w led headlight replacement bulbs represents a significant leap forward in automotive lighting technology, offering a compelling blend of high luminosity and remarkable energy efficiency. For wholesalers, retailers, and informed buyers, understanding the core engineering behind these products is crucial. While much attention is rightly paid to metrics like lumens and color temperature, the single most critical factor determining the performance, longevity, and reliability of any LED headlight is its ability to manage heat. Contrary to popular belief, LED chips are highly sensitive to temperature. While they produce significantly less radiant heat than halogen bulbs, the semiconductor junction itself generates heat during operation. If this heat is not efficiently drawn away and dissipated, it leads to a cascade of detrimental effects, including accelerated lumen depreciation, a sharp decline in operational lifespan, and potential catastrophic failure. Therefore, the sophistication of a bulb’s heat dissipation system is the true differentiator between a high-quality, durable product and a substandard one.

The Critical Link Between Heat and LED Degradation

To fully appreciate the necessity of advanced thermal management, one must first understand the precise ways in which excessive heat negatively impacts LED performance. An LED chip is a solid-state semiconductor device, and its properties are intrinsically linked to its operating temperature.

Lumen Depreciation and Color Shift are the most immediate consequences of poor heat management. When an LED chip operates above its optimal temperature range, the efficiency of the phosphor conversion and the inherent properties of the semiconductor material are compromised. This results in a measurable decrease in light output. A bulb that initially produces a bright, white light can quickly become dimmer and may develop an undesirable color shift over time. This is a primary reason why some 26w led headlight replacement bulbs fail to maintain their advertised brightness after only a short period of use.

Perhaps the most significant impact is on Operational Lifespan. The projected 30,000 to 50,000-hour lifespan commonly associated with LED technology is entirely contingent upon the junction temperature being kept within strict limits. For every sustained increase of 10°C above the recommended junction temperature, the lifespan of the LED can be reduced by as much as 50%. This inverse exponential relationship between temperature and longevity is a fundamental principle of LED reliability. Therefore, a robust cooling system is not merely an accessory; it is the very component that unlocks the legendary durability of LEDs.

Furthermore, excessive heat can lead to Physical Damage to Components. The various materials that constitute a headlight bulb—including the solder joints connecting the LED to the board, the wiring, and the driver circuitry—have different coefficients of thermal expansion. Repeated cycles of intense heating and cooling can cause stress fractures in solder joints, leading to flickering or complete failure. The driver, which regulates power to the LED, is also highly sensitive to heat and can malfunction if its operating environment becomes too hot. In essence, effective heat dissipation is the cornerstone upon which the performance promises of 26w led headlight replacement bulbs are built, making it a top priority for manufacturers and a key consideration for buyers.

Passive Cooling Systems: The Foundation of Heat Dissipation

The vast majority of 26w led headlight replacement bulbs rely on passive cooling systems, which operate without moving parts and instead dissipate heat through conduction, convection, and radiation. The design and material composition of these systems are paramount to their effectiveness.

Material Science: Aluminum Alloys and Ceramic Substrates

At the heart of every passive cooling system is the material used to construct the heat sink. The primary function of this component is to absorb thermal energy from the LED chip and spread it over as large a surface area as possible, where it can then be transferred to the surrounding air.

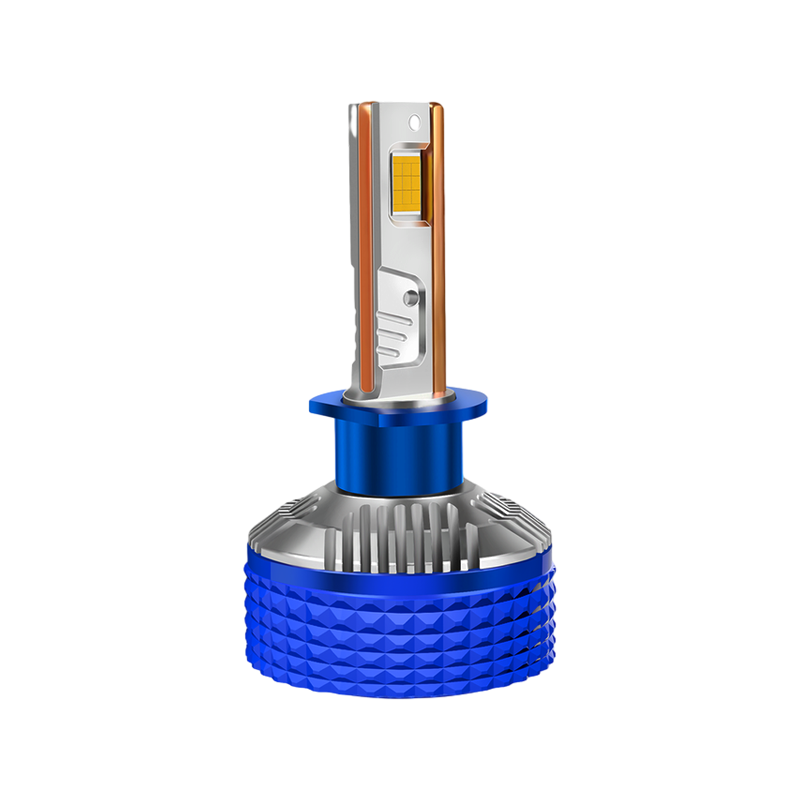

Aluminum alloys are the most prevalent material due to their excellent thermal conductivity, relatively low cost, and favorable weight-to-strength ratio. High-quality 26w led headlight replacement bulbs often use alloys that are specifically formulated for optimal heat transfer. The aluminum acts as a thermal conduit, pulling heat away from the base of the bulb where the LED is mounted. The effectiveness of an aluminum heat sink is directly related to its mass and, more importantly, its design, which we will explore in the next section.

For superior performance, some advanced bulbs utilize ceramic substrates or composite materials. Ceramic offers several distinct advantages. Firstly, it possesses very high thermal conductivity, often surpassing that of standard aluminum. Secondly, and critically, ceramic is an electrical insulator. This allows it to be placed in direct contact with the LED chip and driver components without risk of short circuits, enhancing both safety and thermal transfer efficiency. While more expensive, the use of ceramic is a strong indicator of a product engineered for maximum thermal performance and longevity, a key point of differentiation for discerning buyers in the led headlight bulbs wholesale market.

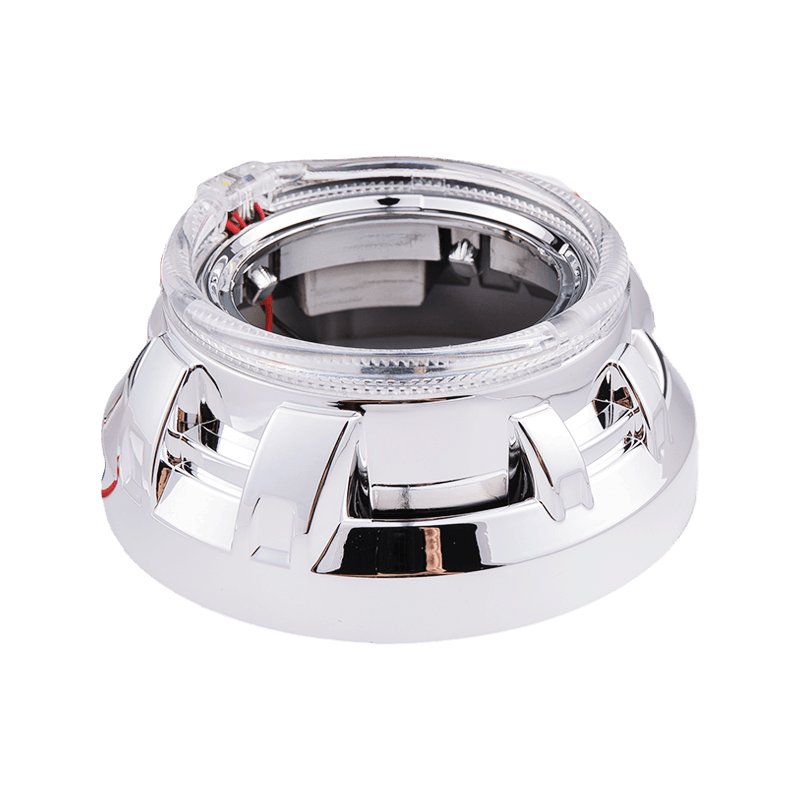

Engineering Design: The Role of Fins and Surface Area

The material alone is insufficient; its physical design is what unlocks its full potential. This is where engineering principles come to the forefront. The most visible aspect of a heat sink is its fins. These thin, protruding structures are meticulously designed to maximize the surface area in contact with the ambient air. A greater surface area facilitates more efficient heat transfer via convection, where heat is carried away by the natural movement of air.

The design of these fins is a careful balance. More fins create more surface area, but if they are too closely spaced, they can trap heat and impede airflow. Modern designs often feature staggered, asymmetrical, or densely packed fin structures that are optimized through computational fluid dynamics to create turbulent airflow, which is more effective at carrying away heat than laminar flow. When evaluating different 26w led headlight replacement bulbs, the size, density, and overall design complexity of the finned heat sink can serve as a visual cue to the level of engineering investment. A larger, more intricately designed heat sink generally signifies a product built to handle thermal loads more effectively, directly addressing the buyer priority of product reliability and reduced return rates.

Active Cooling Systems: Enhancing Performance in Compact Spaces

As the demand for more powerful light output in smaller form factors grows, passive cooling can sometimes reach its physical limits. This is particularly relevant for bulbs that must fit into confined headlight housings originally designed for halogen bulbs. To address this challenge, many manufacturers of 26w led headlight replacement bulbs have incorporated active cooling systems.

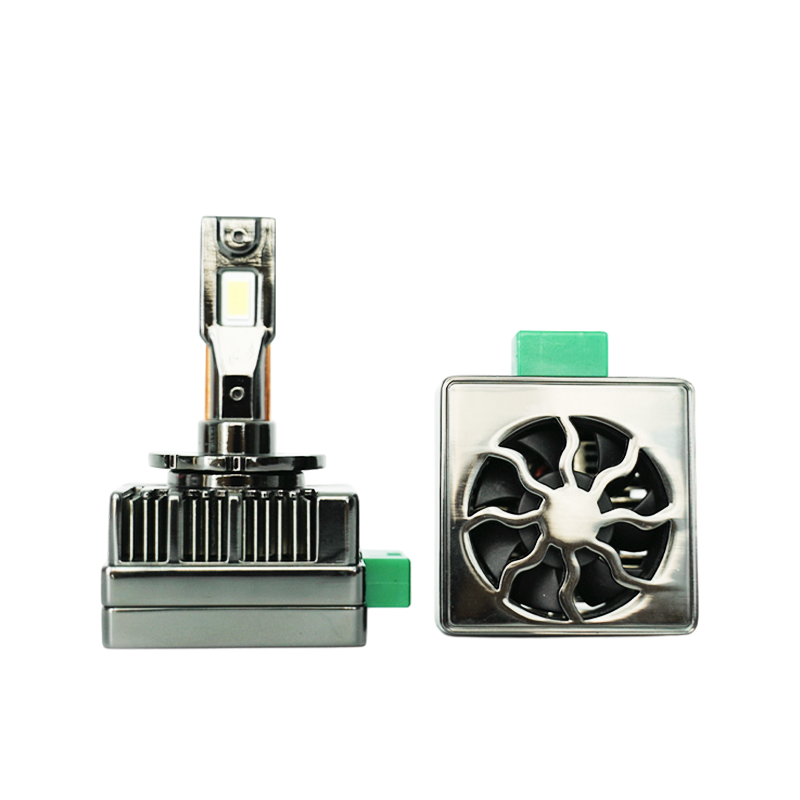

The Prevalence and Evolution of Cooling Fans

The most common form of active cooling is the integration of a miniature, high-speed DC brushless fan. This fan is typically mounted at the base of the bulb, directly behind the heat sink. Its purpose is to forcibly move air across the fins of the heat sink, dramatically increasing the rate of heat exchange compared to passive convection alone. This forced airflow allows a 26w led headlight replacement bulb to maintain a safe operating temperature even in poorly ventilated headlight assemblies.

The technology in these fans has evolved significantly. Early models were often criticized for their noise and relatively short lifespans. Modern versions, however, are a study in miniaturization and durability. They use hydrodynamic bearings or similar long-life technologies to ensure they can operate reliably for thousands of hours, often outlasting the vehicle itself. The focus for manufacturers is on creating a fan that is not only powerful but also quiet and resistant to the vibrations and temperature extremes of the automotive environment. For buyers, understanding that a fan is a precision component, not just an add-on, is essential when assessing product quality.

Fanless Designs and Their Reliance on Superior Passive Cooling

It is important to note that the presence of a fan is not an absolute indicator of superior quality, nor is its absence a sign of inferiority. A significant segment of the market consists of high-quality, fanless 26w led headlight replacement bulbs. These models rely exclusively on the principles of passive cooling discussed earlier, but executed to a very high standard.

A well-designed fanless bulb will typically feature a large, heavy heat sink made from a high-grade aluminum alloy or ceramic. The absence of a fan eliminates a potential point of mechanical failure, which can be a selling point for customers concerned about long-term reliability. The success of a fanless design is entirely dependent on the bulb being installed in a headlight housing that allows for adequate natural airflow around the heat sink. For wholesalers, offering both actively cooled and high-performance passive-cooled 26w led headlight replacement bulbs allows them to cater to a wider range of vehicle applications and customer preferences.

The Integration of Thermal Management: From Chip to Heat Sink

A sophisticated heat sink, whether passive or active, is ineffective if the heat from the LED chip cannot reach it efficiently. This is where the often-overlooked interface materials and board technologies come into play, forming a critical part of the thermal pathway.

Thermal Interface Materials (TIMs), such as thermal pads or thermally conductive pastes, are used to fill microscopic air gaps between the LED board and the main heat sink. Air is a poor conductor of heat, and these gaps can create significant thermal resistance. High-performance TIMs are specially formulated to have high thermal conductivity, ensuring a seamless and efficient transfer of heat from the source to the dissipation unit. The quality of this interface material is a subtle but important detail in the overall thermal management system.

Furthermore, the Printed Circuit Board (PCB) itself plays a role. Standard FR4 PCBs are poor thermal conductors. High-end 26w led headlight replacement bulbs often use Metal-Core Printed Circuit Boards (MCPCBs), particularly those with an aluminum core. In an MCPCB, the circuit layer is bonded to a metal baseplate, which acts as an integral part of the heat spreading system, drawing heat away from the individual LED chips and transferring it directly to the primary heat sink. This integrated approach to thermal design, considering every step from the semiconductor junction to the ambient air, is what separates premium products from the rest.

The following table summarizes the key components of the thermal pathway in a typical 26w led headlight replacement bulb:

| Component | Primary Function | Key Characteristics |

|---|---|---|

| LED Chip/Junction | The source of heat generation. | Efficiency directly impacts amount of waste heat. |

| Thermal Interface Material | Bridges the gap between the board and heat sink. | High thermal conductivity; fills microscopic air pockets. |

| PCB (MCPCB preferred) | Provides electrical connectivity and initial heat spreading. | Metal core (e.g., aluminum) vastly improves heat transfer from chip. |

| Primary Heat Sink | Absorbs and spreads heat over a large area. | Made of high-conductivity aluminum or ceramic; features finned design for surface area. |

| Cooling Fan (Active Systems) | Forces air over the heat sink to enhance cooling. | Brushless, high-speed, long-life bearing design for reliability. |

Evaluating Quality and Performance for the Market

For wholesalers and professional buyers, making informed sourcing decisions requires moving beyond superficial specifications and developing a critical eye for the engineering that underpins thermal management.

Key Indicators of Effective Thermal Design include the physical heft and feel of the heat sink. A substantial, weighty heat sink often suggests a greater mass of thermally conductive material. The design of the fins should be intricate and purposeful, not merely cosmetic. For active-cooled bulbs, inquiring about the type of bearing used in the fan (e.g., hydrodynamic vs. sleeve) can provide insight into its expected lifespan. Furthermore, a clear and detailed explanation of the thermal management system in the product documentation is often a positive sign of a manufacturer’s confidence and transparency.

It is also vital to understand the relationship between power and thermal load. A 26w led headlight replacement bulb is designed to manage the thermal output of its 26-watt power draw. It represents an engineering balance, providing substantial light output—often equivalent to much higher-wattage halogen bulbs—while generating a manageable amount of heat that can be effectively dissipated by a well-designed cooling system. This balance is crucial for ensuring the longevity and performance that the market expects from LED technology. Products that fail to strike this balance will inevitably lead to customer dissatisfaction and increased warranty claims.

Conclusion: Heat Dissipation as a Core Value Proposition

In conclusion, the key heat dissipation technologies in modern 26w led headlight replacement bulbs are not merely ancillary features; they are fundamental to the product’s value proposition. The transition from simple aluminum heat sinks to advanced systems incorporating high-conductivity ceramics, meticulously engineered fin structures, and reliable active fans represents the maturation of LED automotive lighting. For those in the business of supplying these products, a deep understanding of thermal management principles is indispensable. It allows for the differentiation of quality products from inferior ones, enables informed conversations with retailers and end-users, and ultimately supports a business model built on reliability and customer satisfaction. As the market for 26w led headlight replacement bulbs continues to grow and evolve, the pursuit of ever-more efficient and compact cooling solutions will remain at the forefront of product innovation, ensuring that these bulbs deliver on their promise of brilliant, safe, and long-lasting illumination.

English

English Español

Español عربى

عربى русский

русский