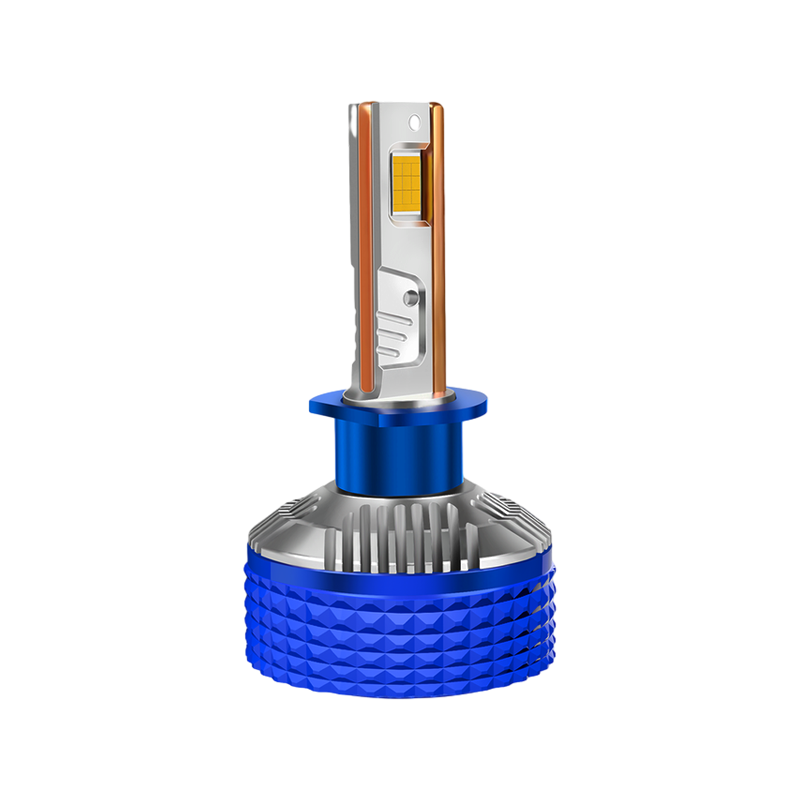

The 6063 aluminum profile led headlight bulb has become an integral component in modern automotive lighting systems due to its combination of lightweight characteristics, structural rigidity, and excellent thermal conductivity. As automotive designs evolve toward more compact and efficient architectures, the demand for optimizing packaging density within headlamp modules has grown.

Understanding Packaging Density in Automotive Lamps

Packaging density refers to the efficient utilization of space within a lamp assembly to accommodate lighting components, heat management systems, electronics, and structural supports. Higher packaging density enables:

- Reduced overall lamp size, contributing to slimmer vehicle designs.

- Integration of advanced functionalities such as adaptive lighting or dynamic beam shaping.

- Enhanced assembly flexibility and simplified module integration.

The challenge lies in achieving this density while ensuring sufficient heat dissipation and mechanical stability. 6063 aluminum profile led headlight bulb housings play a pivotal role in this optimization due to their versatile extrusion capabilities and high surface area-to-volume ratio.

Role of Compact 6063 Aluminum Profiles

Compact designs of 6063 aluminum profiles provide a pathway to increase packaging density without compromising performance. The primary contributions include:

1. Material Efficiency

6063 aluminum combines lightweight properties with high structural rigidity, enabling thinner walls and reduced cross-sectional areas without losing mechanical strength. This allows designers to allocate more internal space for optical and electronic components.

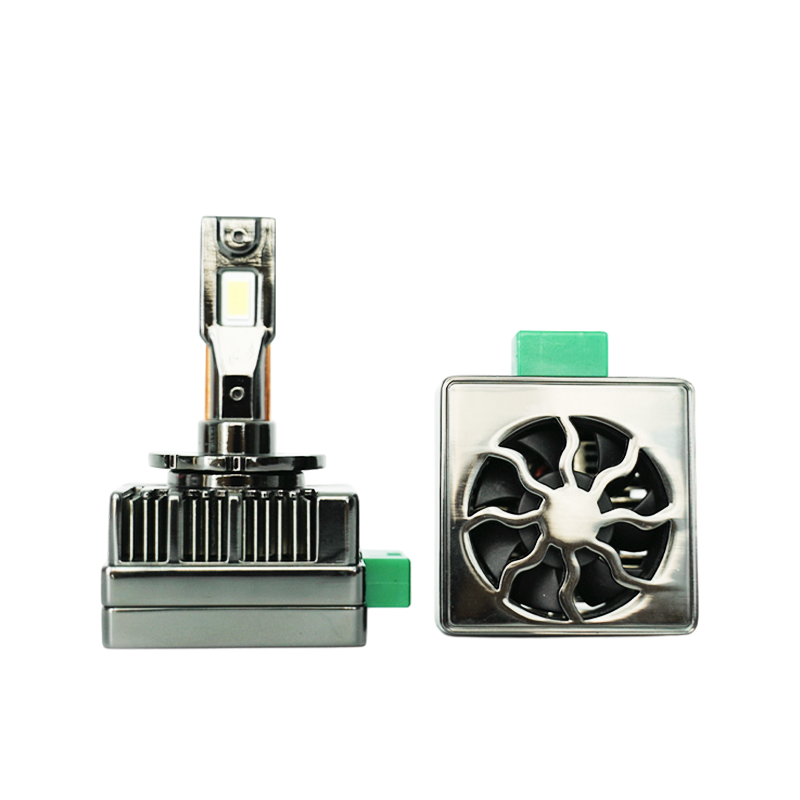

2. Enhanced Thermal Management

Thermal efficiency is critical for led headlight bulbs, where excessive heat can reduce luminous efficacy and component lifespan. Compact 6063 profiles can be designed with optimized fin geometry and increased surface contact area, enabling effective passive heat dissipation. The result is reduced spacing requirements for heat sinks and greater overall packaging density.

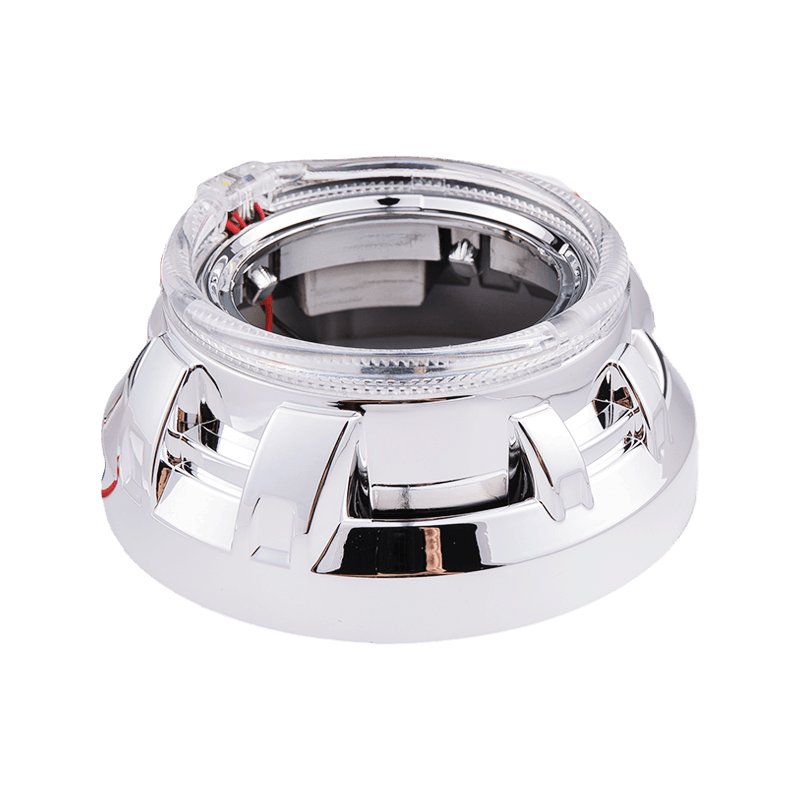

3. Integration of Multi-Functional Elements

Compact aluminum profiles can incorporate channels, mounting points, and cooling fins within a single extrusion. This multifunctionality reduces the need for additional parts, minimizes assembly complexity, and allows tighter packing of electronic drivers, optical lenses, and protective covers.

4. Geometric Flexibility

6063 aluminum supports complex cross-sectional shapes, including hollow structures, internal ribs, and interlocking features. These design options enable high-density arrangements while maintaining alignment precision and structural integrity.

System-Level Considerations

Optimizing packaging density requires evaluating automotive lamp assemblies as integrated systems, not as isolated components. Several factors influence how compact profiles can be effectively employed:

Mechanical Design Constraints

- Vibration Resistance: Vehicles experience dynamic loads, and the aluminum profile must resist flexing without transferring stress to sensitive LED chips or lenses.

- Tolerance Management: High-density arrangements reduce allowable assembly tolerances, requiring precise extrusion control and post-processing.

- Crash and Impact Performance: Compact profiles must provide adequate rigidity to maintain shape and protect internal components during minor collisions or impacts.

Thermal Performance

- Heat Path Optimization: Dense packing can create thermal bottlenecks. Integrating heat channels and enhancing surface emissivity helps mitigate this risk.

- Material Conductivity: 6063 aluminum’s thermal conductivity (~200 W/m·K) supports efficient heat spreading, enabling tighter spatial arrangements of LEDs and drivers.

- Cooling Surface Area: Fin design and profile segmentation directly influence thermal performance in compact spaces.

Optical Integration

- Light Distribution Requirements: Compact profiles must accommodate precise optical elements without introducing beam distortions.

- Lens and Reflector Alignment: Reduced spacing requires careful design to avoid interference between reflective surfaces and housing walls.

- Modular Optical Units: Integration of optical units into profile cavities can reduce overall lamp volume.

Manufacturing and Assembly Considerations

- Extrusion Tolerances: Tight design geometries require precise control of extrusion parameters.

- Secondary Operations: Machining, anodizing, or surface treatment processes must maintain dimensional stability to support dense packing.

- Assembly Efficiency: Profiles with integrated mounting features reduce assembly time and simplify automated production.

Comparative Analysis of Compact vs Conventional Profiles

| Feature | Conventional 6063 Profiles | Compact 6063 Profiles | Effect on Packaging Density |

|---|---|---|---|

| Wall Thickness | 2.0-3.0 mm | 1.2-1.5 mm | Thinner walls free internal space |

| Thermal Fins | Separate heat sink required | Integrated micro-fins | Reduced external footprint |

| Mounting Features | Additional brackets | Built-in channels | Less component stacking |

| Weight | Higher | Lower | Allows smaller supporting structures |

| Cross-Section Complexity | Simple shapes | Hollow and multi-rib | Optimized volume utilization |

Case Study: Heat Management in Compact Profiles

A typical LED headlight module with conventional profiles occupies ~20% more internal volume for heat dissipation components. Using compact 6063 aluminum profile led headlight bulb designs with integrated fins, the internal space required for thermal management is reduced by ~30%, allowing the placement of additional optical elements or driver electronics without increasing lamp size.

Multi-Functional Design Approaches

Several design strategies can maximize packaging density using compact aluminum profiles:

1. Nested Channel Design

Profiles can integrate nested channels to route power lines, coolant paths, or mounting guides, minimizing the need for additional space-consuming conduits.

2. Interlocking Extrusions

Modular interlocking profiles enable multiple components to be stacked efficiently while preserving alignment and mechanical stability.

3. Hollow Structural Sections

Hollow sections provide high strength-to-weight ratios and create cavities for electronic components or lenses, reducing external volume requirements.

4. Integrated Heat Sinks

Micro-fin geometries within the profile increase surface area without enlarging the housing, maintaining both thermal performance and compactness.

| Design Strategy | Primary Benefit | Impact on Packaging Density |

|---|---|---|

| Nested Channels | Space for wires and coolant | Minimizes auxiliary components |

| Interlocking Extrusions | Alignment and modular stacking | Enables tighter component placement |

| Hollow Sections | Structural strength | Provides internal storage for electronics |

| Integrated Heat Sinks | Thermal efficiency | Reduces volume required for cooling |

Considerations for High-Volume Production

- Process Repeatability: Consistent extrusion and secondary processing are critical to maintain dense packaging specifications.

- Surface Treatments: Anodizing and coating must preserve fine features without reducing tolerances.

- Inspection and Quality Control: Non-destructive testing methods ensure the profile maintains structural and thermal performance despite compact design.

Summary

Compact 6063 aluminum profile led headlight bulb designs contribute to higher packaging density in automotive lamps by combining material efficiency, thermal management, and geometric flexibility. From a systems perspective, these profiles enable tighter integration of optical, thermal, and electronic components while maintaining structural integrity. Multi-functional extrusion strategies, hollow sections, and integrated heat sinks allow internal space to be utilized more effectively. Proper mechanical design, thermal analysis, and precise manufacturing processes are essential to ensure performance is not compromised in dense packaging arrangements.

FAQ

Q1: How does 6063 aluminum compare to other aluminum alloys for high-density lamp packaging?

A1: 6063 aluminum offers a balanced combination of lightweight properties, extrusion flexibility, and thermal conductivity, making it suitable for compact, dense lamp designs where space and heat management are critical.

Q2: Can compact profiles handle high-power LEDs without additional cooling?

A2: Properly designed compact profiles with integrated micro-fins and optimized surface area can passively dissipate heat for medium to high-power LED modules, though extreme power densities may still require active cooling.

Q3: How do manufacturing tolerances affect packaging density?

A3: Tight tolerances are critical. Even small deviations in extrusion or machining can reduce available space for internal components, compromising alignment and thermal performance.

Q4: Are hollow profiles more efficient for space utilization?

A4: Yes, hollow sections provide cavities for electronics or optical components while maintaining structural strength, significantly improving internal space efficiency.

Q5: How can integrated features reduce assembly complexity?

A5: Features such as built-in mounting channels, interlocking geometries, or cable routing paths reduce the number of separate components and simplify automated assembly, contributing to efficient high-density designs.

References

- Jiecheng Auto. (2025). Technological Innovation and Improvement of Lighting Performance in 6063 Aluminum Profile LED Headlight Bulbs.

- ZP Aluminium. (2025). LED Housing and Heat Sink Extrusions: Technical Specifications.

- Pailian Aluminium. (2025). Industrial LED Aluminum Profiles with Heatsink Design Guidelines.

- Bliauto. (2025). Sourcing LED Headlight Materials: Engineering Considerations.

- Reports and Data. (2025). Global LED Headlight Bulb Market Insights and Trends.

English

English Español

Español عربى

عربى русский

русский