The integration of single beam led headlight bulb technology into modern vehicles has significant implications for the overall electrical architecture. Unlike traditional halogen or HID lighting, LEDs demand careful consideration of power management, thermal regulation, signal integrity, and control logic. From a systems engineering perspective, this integration influences multiple subsystems including power distribution, electronic control units (ECUs), wiring harness design, diagnostic frameworks, and communication networks.

Electrical Load Management

1. Reduced Peak Current Demand

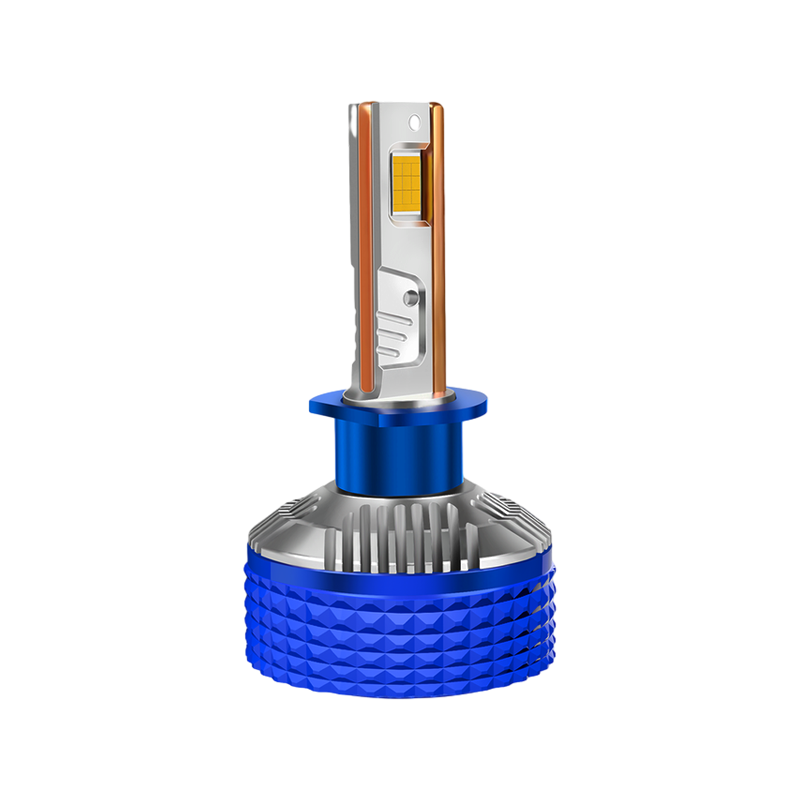

LED headlights inherently require less power compared to halogen or HID units. A single beam led headlight bulb typically operates in the range of 20-50 watts, compared to 55-65 watts for halogen. Despite the lower power draw, the integration of multiple LED modules across the vehicle requires recalibration of the electrical system to handle distributed load and ensure voltage stability.

2. Dynamic Load Variations

LED headlights are often used in conjunction with adaptive lighting systems or dimming functionalities. This dynamic operation introduces fluctuating current demands. The vehicle’s electrical system must accommodate these variations without causing voltage dips that could affect sensitive ECUs.

3. Impact on Alternator and Battery

Lower overall current draw reduces strain on the alternator and improves fuel efficiency in combustion vehicles. For electric vehicles (EVs), optimized LED power consumption extends driving range. Table 1 illustrates a comparative overview of typical power requirements across lighting types.

| Lighting Type | Typical Power Consumption | Peak Current (A) | Voltage Stability Requirements |

|---|---|---|---|

| Halogen | 55-65 W | 4.5-5.5 | Standard 12 V ± 0.5 V |

| HID | 35-50 W | 3.0-4.2 | 12 V ± 0.3 V |

| Single Beam LED | 20-50 W | 1.7-4.2 | 12 V ± 0.2 V |

Wiring Harness and Connector Considerations

1. Reduced Conductor Size

Due to lower current requirements, wiring harnesses for LED headlights can utilize smaller gauge wires. This reduction in conductor size reduces weight and potential space utilization within vehicle body channels. However, care must be taken to prevent voltage drops over long cable runs, particularly in vehicles with extended lighting layouts.

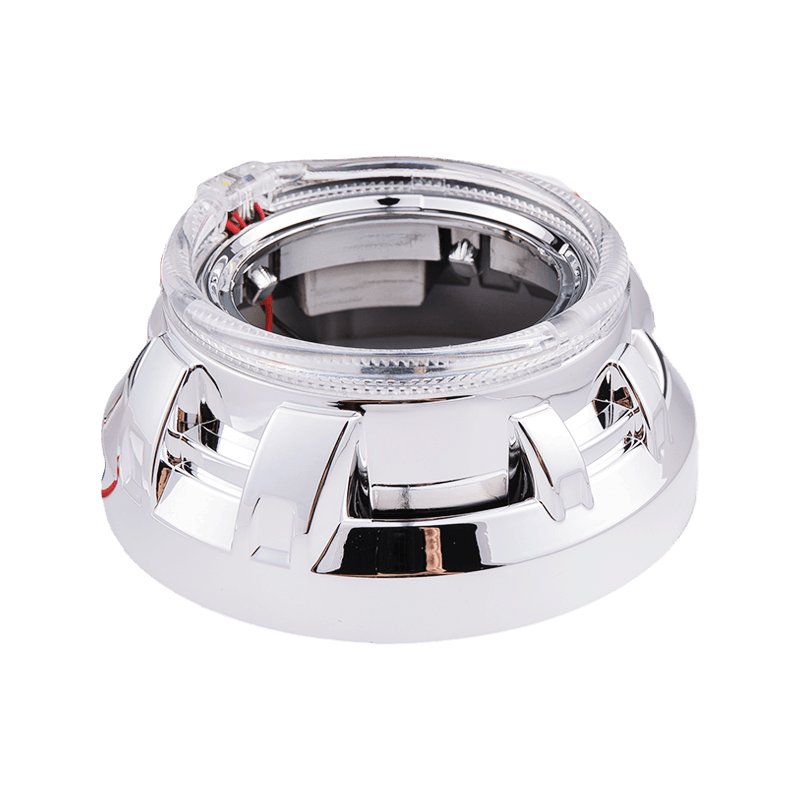

2. Connector Design

LED modules require reliable low-resistance connectors to maintain signal integrity. Poor connections can result in flickering or voltage irregularities. High-quality connectors with proper sealing and corrosion resistance are essential, particularly for off-road or high-moisture environments.

3. Modular Harness Integration

To facilitate serviceability and modularity, harnesses are often designed with plug-and-play interfaces for LED headlights. This design requires thoughtful placement of junctions and routing channels to minimize electromagnetic interference and mechanical stress.

Control and Communication Architecture

1. PWM Dimming and Control Signals

Many single beam led headlight bulb systems employ pulse-width modulation (PWM) for brightness control. Implementing PWM requires integration with the vehicle’s body control module (BCM) or dedicated lighting control ECU. Timing accuracy and signal fidelity are critical to prevent flicker or synchronization issues across multiple lighting channels.

2. Diagnostic Feedback and Fault Detection

LED modules often incorporate diagnostic feedback to monitor temperature, voltage, and operational status. Integration into the vehicle’s communication network, such as CAN or LIN buses, allows real-time fault detection and proactive maintenance alerts. This necessitates software development in ECUs to interpret and react to LED-specific diagnostic data.

3. Adaptive and Matrix Lighting Integration

While single beam LEDs are simpler than full matrix systems, many vehicles now incorporate adaptive beam control, which requires communication between headlight modules and vehicle navigation or sensor systems. Electrical architecture must support low-latency, high-integrity data transmission for accurate beam shaping.

Thermal Management and Electrical Interaction

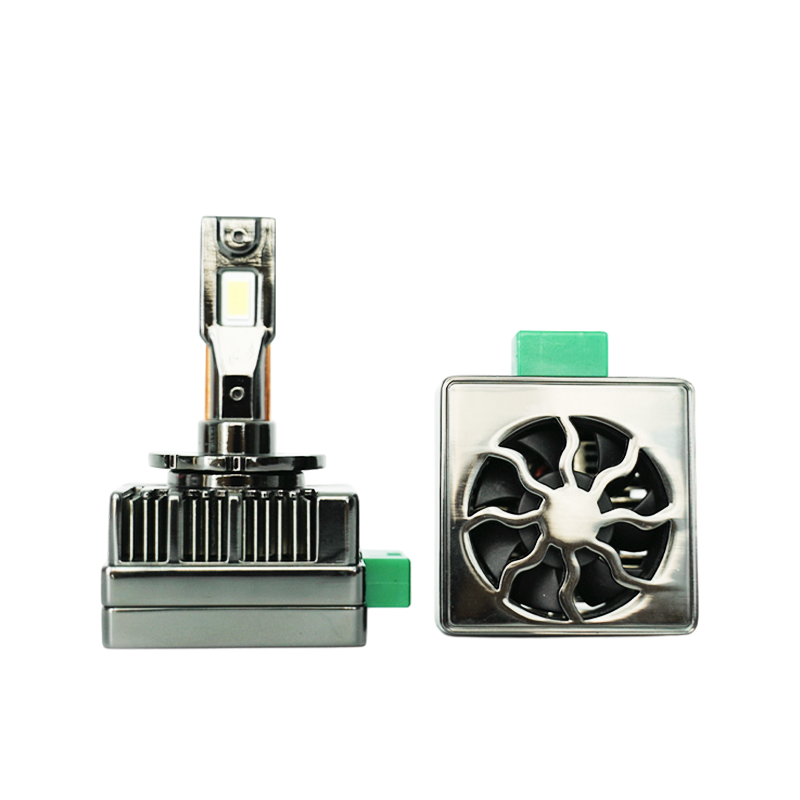

1. Heat Dissipation Requirements

Despite lower power consumption, LEDs generate heat at the semiconductor junctions. Effective thermal management ensures longevity and consistent luminous output. The electrical architecture must incorporate feedback from thermal sensors to adjust current supply and prevent overheating.

2. Interaction with Vehicle HVAC and Cooling Systems

In some designs, headlight thermal management may involve active cooling, such as dedicated fans or liquid cooling channels. The electrical system must provide stable power for these subsystems while coordinating with the vehicle’s main cooling circuits to avoid overloading the power supply.

System-Level Integration Challenges

1. Voltage Stability Across Modules

Integrating LED headlights requires careful voltage regulation, particularly in vehicles with extensive electronic subsystems. Fluctuations can propagate to sensitive modules, affecting infotainment, ADAS sensors, or other safety-critical electronics.

2. Electromagnetic Compatibility (EMC)

LED drivers and PWM signals can generate high-frequency noise. Vehicle electrical architecture must mitigate EMC risks through shielding, filtering, and grounding strategies, ensuring compliance with automotive EMC standards.

3. Scalability and Future Upgrades

Designing the electrical system with LED integration in mind improves scalability for future upgrades, such as additional lighting modules, matrix systems, or exterior communication lighting. Modular power distribution units (PDUs) and adaptable bus structures enhance flexibility for system evolution.

| Integration Aspect | Traditional Halogen HID Systems | LED Systems (Single Beam) |

|---|---|---|

| Power Demand | High, steady | Low, dynamic PWM-enabled |

| Thermal Load | Moderate, passive cooling | Targeted, active/passive |

| Control Signals | Minimal, on/off | PWM, CAN/LIN integrated |

| Diagnostics | Limited | Advanced, real-time feedback |

| EMC Risk | Low | Moderate, requires filtering |

Implications for Vehicle Design

1. Space Optimization

LED headlights allow more compact assembly, freeing space for other vehicle components. Electrical architecture planning must account for revised harness routing and module placement.

2. Safety and Redundancy

Critical safety requirements, such as automatic headlight failure detection and fallback strategies, must be integrated into the electrical architecture to comply with regulatory standards.

3. Lifecycle Management

The modular and digital nature of LED headlights simplifies service and replacement procedures but also requires software version management, calibration routines, and firmware updates within the electrical control framework.

Summary

Integrating single beam led headlight bulb technology into vehicles significantly impacts electrical architecture. From load management and wiring design to control systems, thermal regulation, and system-level reliability, each aspect requires careful consideration. The shift from traditional lighting to LED systems necessitates a holistic approach, ensuring voltage stability, EMC compliance, thermal performance, and diagnostic capability. Effective integration results in enhanced system efficiency, improved longevity, and supports scalability for future adaptive lighting technologies.

FAQ

Q1: How does LED integration affect battery life in electric vehicles?

A1: Lower power consumption of LEDs reduces overall electrical load, extending vehicle range and reducing stress on the battery management system.

Q2: Are additional ECUs required for single beam LED headlights?

A2: Not necessarily. While some vehicles use a dedicated lighting control ECU, many systems integrate control within existing body or central control modules.

Q3: What are common issues with LED headlight PWM control?

A3: Flickering, interference with other electronic systems, and voltage ripple are common concerns that must be addressed through signal filtering and proper wiring.

Q4: How is thermal management handled for LED modules?

A4: Through passive heat sinks, active fans, or integration with the vehicle’s cooling system. Electrical architecture must support power distribution to thermal management components.

Q5: Can LED headlights be retrofitted without redesigning the electrical system?

A5: Minor retrofits are possible, but optimal performance often requires recalibration of voltage regulation, diagnostic integration, and harness compatibility.

References

- Automotive Lighting Handbook, 2022 Edition. SAE International.

- Bosch Automotive Handbook, 10th Edition, 2021.

- “Trends in Automotive LED Lighting,” Journal of Automotive Electronics, Vol. 35, Issue 2, 2023.

- ISO 16750: Road Vehicles – Environmental Conditions and Testing for Electrical and Electronic Equipment.

- IEC 61966-2-1: Multimedia Systems and Equipment – Colour Measurement and Calibration Standards.

English

English Español

Español عربى

عربى русский

русский