In the technological innovation of aviation-grade 6063 aluminum profile LED headlight bulbs, the processing performance of the material is becoming the core element to break through the heat dissipation bottleneck. Different from the traditional design that simply relies on the thermal conductivity of the material, 6063 aluminum profiles, with their plasticity and mechanical processing adaptability, construct a complex heat dissipation structure through precision molding technology, forming a synergistic heat dissipation effect at the micro-scale and macro-design level, bringing a new thermal management solution to the LED lighting system.

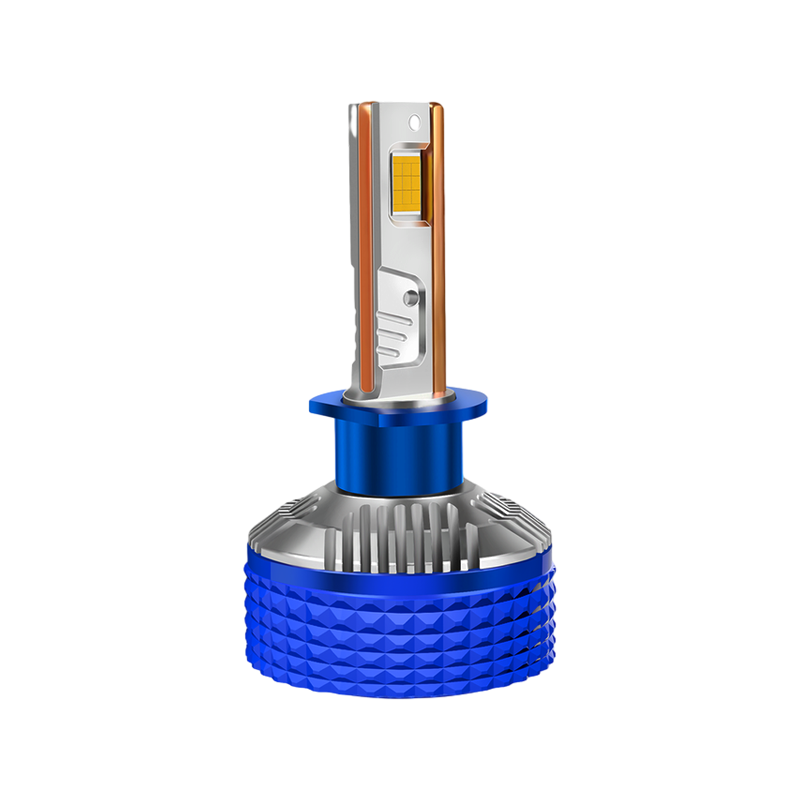

The crystal structure characteristics of 6063 aluminum profiles lay the foundation for precision machining. Its uniform α-Al matrix and dispersed Mg₂Si strengthening phase give the material moderate hardness and ductility, which not only ensures that the surface accuracy will not be lost due to excessive softness during processing, but also avoids the tool wear problem caused by excessive hardness. In the extrusion molding process, the 6063 aluminum ingot is plastically deformed at high temperature to form a highly oriented fibrous structure along the extrusion direction. This anisotropic structure not only improves the material strength, but also forms a continuous heat conduction channel in the heat dissipation direction. Through mold design optimization, the extrusion accuracy of the profile can be controlled at the micron level to ensure that the key parameters such as the spacing and thickness of the heat dissipation fins meet the dual requirements of fluid mechanics and thermodynamics.

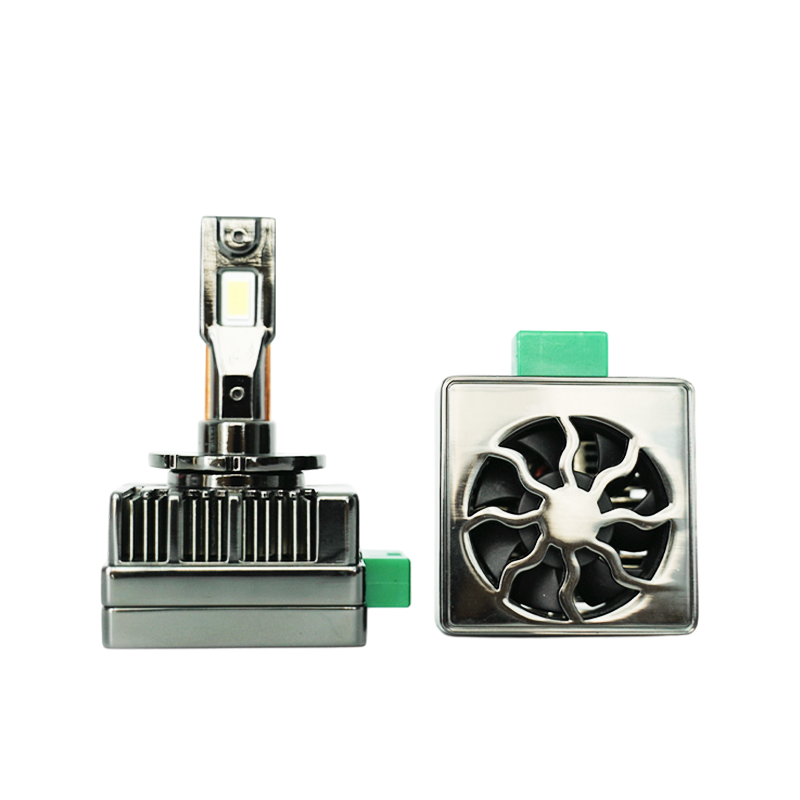

The innovative design of the heat dissipation structure relies heavily on the processing potential of the 6063 aluminum profile. Traditional flat heat sinks have natural limitations in air convection efficiency, while 6063 aluminum profiles can be used through composite processes such as extrusion, milling, and die-casting to construct a bionic heat dissipation fin array. These fins are designed with hyperbolic guide surfaces to increase the surface area utilization several times in a limited space. When the airflow passes over the surface of the fin, the vortex effect generated by the curved surface destroys the boundary layer and promotes rapid heat removal. The gradient distribution structure between the fins forms a self-induced airflow channel, which enables the air to form directional convection inside the lamp body, significantly improving the heat dissipation efficiency. The realization of this precision structure is due to the high adaptability of 6063 aluminum profiles to CNC machining, which ensures that the machining error of complex curved surfaces is controlled at the sub-millimeter level.

In the manufacturing of integrated heat dissipation modules, 6063 aluminum profiles show unique process integration advantages. Through solid-phase connection technologies such as stir friction welding, the extruded heat dissipation fins can be seamlessly combined with the lamp body base to avoid the problems of pores and thermal stress concentration caused by traditional welding processes. This all-aluminum integrated structure not only enhances the efficiency of heat conduction, but also improves the structural strength and vibration resistance of the components. For the local high-heat area of the LED chip, precision CNC machining technology can be used to construct a microchannel heat dissipation structure inside the profile, and phase change material filling can be used to achieve fixed-point heat dissipation. This multi-level heat dissipation design from macro to micro maximizes the processing performance of 6063 aluminum profiles.

In actual application scenarios, the heat dissipation structure based on 6063 aluminum profile processing shows significant performance advantages. In extreme environment tests, even when working continuously in a high temperature environment of 80℃, the surface temperature of the lamp body can still be maintained within the safe threshold, ensuring the stable working temperature of the LED chip. The anti-corrosion treatment process of its heat sink fins, combined with the self-repairing properties of the oxide film of the 6063 aluminum profile, shows weather resistance in the salt spray test, effectively avoiding the attenuation of heat dissipation efficiency caused by corrosion. This design that takes into account both performance and reliability enables LED headlight bulbs equipped with a 6063 aluminum profile heat dissipation structure to maintain stable light output performance throughout their life cycle.

From the material crystal structure to the precision molding process, the 6063 aluminum profile has redefined the heat dissipation boundary of LED headlights with its excellent processing performance. By deeply integrating material science and thermal management engineering, this aviation-grade material is driving LED lighting technology towards higher performance and longer life, providing more reliable solutions for automotive lighting, industrial lighting and other fields.

English

English Español

Español عربى

عربى русский

русский