IP68 Waterproof Rating Explained: Why is it a Key Performance Indicator for LED Headlight Bulbs?

As automotive lighting technology continues to innovate, IP68 waterproof rating has become an important yardstick for measuring the performance of LED headlight bulbs. For vehicles, the driving environment is complex and changeable. Whether it is a rainy road, a muddy country road, or a car wash room washed by a high-pressure water gun, the vehicle headlights may be intruded by water and dust. Therefore, a deep understanding of the IP68 standard is of key significance to the reliability and performance improvement of LED headlight bulbs.

(1) Explain the definition of dustproof/waterproof in IP68 standard

IP (Ingress Protection) is an international code for identifying protection levels. The "6" and "8" in IP68 represent the dustproof and waterproof levels respectively. The highest dustproof level is level 6, which means that foreign objects and dust are completely prevented from entering. For LED headlight bulbs, this can effectively prevent dust from entering the bulb, prevent dust from adhering to key components such as chips and circuit boards, and avoid problems such as short circuits and poor heat dissipation caused by dust accumulation, thereby extending the service life of the bulb and ensuring the stability of the lighting system.

The highest waterproof level is level 8, which usually means that the product will not get water when immersed in water of a certain depth within a specified time. Different standards have slightly different requirements for the water depth and immersion time of IP68. Generally, IP68-level LED headlight bulbs can work normally in water at a depth of 1.5 meters for at least 30 minutes. This waterproof performance ensures that the headlight bulbs will not be damaged by water when the vehicle is driving in wading, encountering heavy rain, or even being washed by a high-pressure water gun, ensuring the lighting safety of night driving.

(2) Disadvantages of traditional light bulbs in humid environments

Traditional bulbs, such as halogen bulbs and xenon bulbs, have many disadvantages in humid environments. From a structural point of view, traditional bulbs mostly use glass shells and metal filaments, and their sealing performance is relatively poor. When a vehicle is driving in a humid environment, water vapor in the air can easily enter the interior of the bulb and adhere to the glass shell and filament. When the bulb is lit, the filament heats up and the water vapor evaporates to form water mist, which will cause light scattering, reduce lighting brightness and clarity, and affect the driver's vision.

In addition, water vapor will accelerate the oxidation and corrosion of the filament, shortening the life of the bulb. When encountering a flooded road or heavy rain, once a traditional bulb is flooded, it is very easy to cause a short circuit, causing the bulb to malfunction, and may even cause a vehicle circuit system failure, posing a serious safety hazard. In contrast, LED headlight bulbs with an IP68 waterproof rating can effectively resist the invasion of water and dust through advanced sealing and protection technology, showing stronger environmental adaptability and reliability.

Three core technical advantages of waterproof LED headlight bulbs

The IP68 waterproof LED headlight bulb can work stably in complex environments thanks to the core technology support behind it. These technologies are innovative and optimized in many aspects such as sealing, heat dissipation, and circuit protection, laying a solid foundation for improving the reliability and performance of vehicle lighting systems.

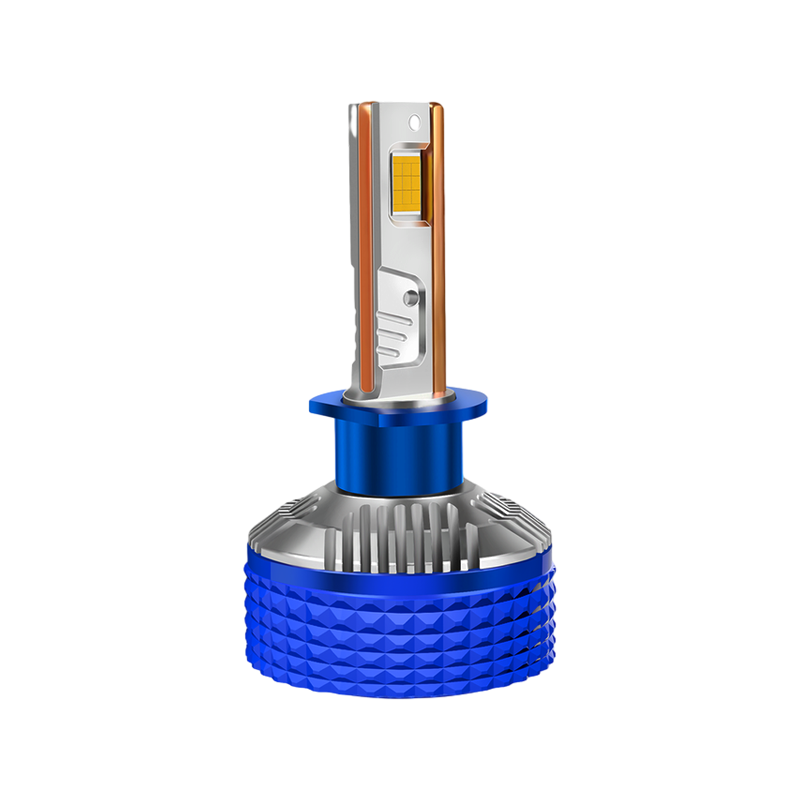

(1) Sealing process and material selection (such as silicone packaging)

Sealing technology and material selection are key to achieving IP68 waterproof rating. Currently, most waterproof LED headlight bulbs use silicone encapsulation technology. Silicone is a high-performance elastomeric material with good flexibility, weather resistance and sealing performance. During the production process, silicone completely wraps key components such as LED chips and circuit boards through mold injection or dispensing to form a tightly sealed space.

The flexibility of silicone enables it to adapt to the deformation caused by temperature changes and mechanical vibrations, and always maintain a good sealing effect. At the same time, silicone also has excellent aging resistance. Even if it is exposed to harsh environments such as ultraviolet rays, high temperature, and humidity for a long time, it is not easy to harden or crack, thereby ensuring the long-term stability of the waterproof and dustproof performance of the bulb. In addition, the silicone material itself has insulation properties, which can effectively prevent circuit short circuits and further improve the safety of the bulb.

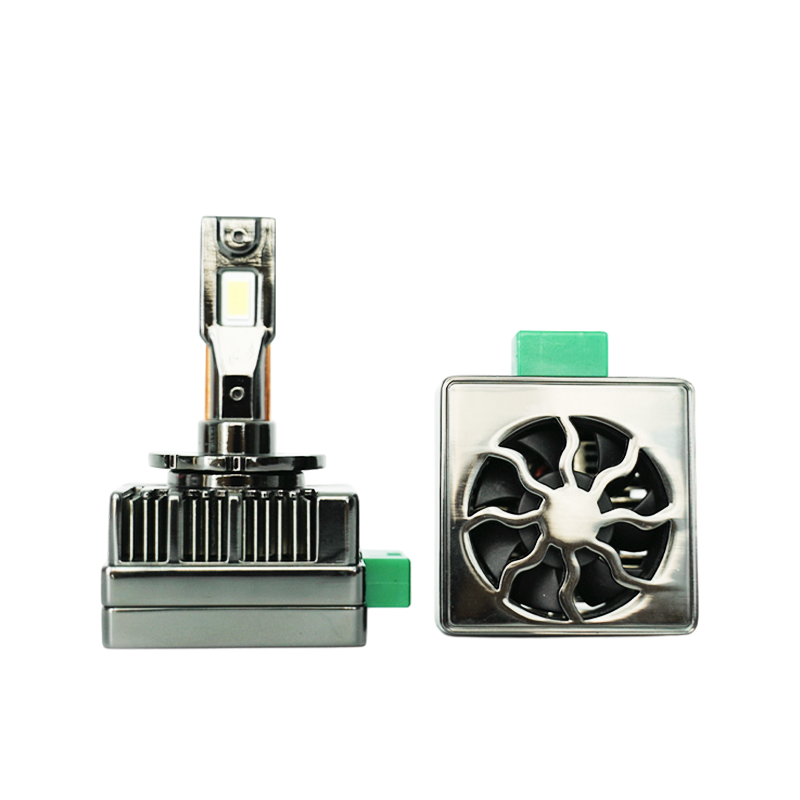

(2) Collaborative implementation of heat dissipation design and waterproof function

LED bulbs generate a lot of heat during operation. If the heat cannot be dissipated in time, the chip temperature will rise, affecting the luminous efficiency and service life. While achieving waterproof function, ensuring good heat dissipation is a major challenge for waterproof LED headlight bulbs. To solve this problem, engineers have adopted a variety of innovative designs.

On the one hand, efficient heat dissipation structures are adopted, such as finned heat sinks and heat pipe heat dissipation. Finned heat sinks increase the heat dissipation area to speed up the conduction and convection of heat to the surrounding air; heat pipe heat dissipation uses the phase change principle of the working fluid inside the heat pipe to achieve fast and efficient heat transfer. On the other hand, in terms of waterproof design, special heat dissipation hole design and waterproof breathable membrane are adopted. The heat dissipation holes can ensure the smooth discharge of heat, and prevent water and dust from entering through the waterproof breathable membrane. The waterproof breathable membrane is breathable and hydrophobic, allowing air to pass freely while preventing water droplets from entering, thereby achieving the synergy of heat dissipation and waterproof functions, ensuring that the bulb can maintain a stable operating temperature in various environments.

(3) Anti-corrosion terminals and circuit protection technology

The working environment of vehicle headlights is not only humid, but also may be affected by various corrosive substances, such as snow melting agents and saline-alkali components on the road. Therefore, waterproof LED headlight bulbs use anti-corrosion terminals and advanced circuit protection technology. Anti-corrosion terminals usually use special metal materials and undergo surface treatment processes such as gold plating and nickel plating to enhance their corrosion resistance and prevent poor contact of the terminals due to corrosion, which affects the normal operation of the bulb.

In terms of circuit protection, multiple circuit protection technologies such as overvoltage protection, overcurrent protection, and short circuit protection are used. When the voltage rises abnormally, the current is too large, or there is a short circuit in the circuit, the protection circuit will act quickly to cut off the power supply to prevent damage to the LED chip and circuit board. At the same time, moisture-proof and mildew-proof circuit board coatings are used to further improve the reliability and stability of the circuit system, ensuring that the bulb can always emit light normally in harsh environments.

Actual application scenario test: IP68 LED bulb performance in extreme environments

To verify the reliability and performance of IP68 waterproof LED headlight bulbs in actual applications, researchers and companies have conducted a series of rigorous extreme environment tests. These tests simulate various harsh working conditions that vehicles may encounter in reality, and demonstrate the excellent performance of the bulbs through specific data.

(1) High-pressure water washing/rainstorm environment test data

In the high-pressure water washing test, the vehicle equipped with IP68 waterproof LED headlight bulbs was placed in a professional car wash and washed with a high-pressure water gun with a pressure of up to 8MPa for 10 minutes. The test results showed that there was no sign of water ingress inside the bulb, all electrical performance indicators were normal, and the light brightness and color temperature did not change significantly.

In the rainstorm environment simulation test, artificial rainfall equipment was used to create an extreme rainstorm environment with a rainfall of 200mm/h, and the vehicle continued to drive for 2 hours in this environment. After the test, the bulb was disassembled and inspected, and it was found that the inside of the bulb was dry, and the circuit and chip were not damaged in any way, and it could still maintain a stable lighting effect. However, under the same test conditions, most traditional bulbs had problems such as water ingress and short circuits and could not work properly.

(2) Impact of temperature difference on light efficiency stability

In order to test the effect of temperature difference on the light efficiency stability of IP68 waterproof LED headlight bulbs, a hot and cold cycle test was conducted. The bulb was first placed in a low temperature environment of -40℃ for 2 hours, then quickly moved to a high temperature environment of 80℃ for 2 hours, and this cycle was repeated 10 times. During the test, the luminous flux, color temperature and other parameters of the bulb were monitored in real time.

The results show that during the entire test process, the luminous flux fluctuation range of the bulb was controlled within ±3%, the color temperature change did not exceed ±200K, and the light efficiency stability was excellent. This is due to the good sealing performance and heat dissipation design of the bulb, which effectively resisted the thermal expansion and contraction caused by temperature differences, prevented water vapor condensation and circuit failures, and ensured that the vehicle lighting system can always provide stable and reliable lighting in environments with large temperature differences, such as the cold early morning in winter and the high temperature at noon, and when driving across different climate zones.

English

English Español

Español عربى

عربى русский

русский