In modern automotive lighting systems, the High Lumens LED Headlight Bulb has become an essential component for improving visibility, energy efficiency, and overall driving safety. While brightness, color temperature, and energy consumption are frequently discussed among buyers, water and dust resistance is an equally critical factor that directly influences the durability and performance of these bulbs.

High Lumens LED Headlight Bulb technology relies on precise electrical components and heat management systems. Any exposure to moisture, dust, or other environmental contaminants can compromise these systems, leading to decreased luminosity, reduced lifespan, or even complete failure.

Understanding Water and Dust Resistance

Water and dust resistance is commonly defined by IP (Ingress Protection) ratings, which indicate the level of protection a device provides against solid particles and liquid intrusion. For automotive lighting applications, High Lumens LED Headlight Bulbs are often designed with varying IP ratings depending on their intended operating environments.

The first digit in the IP rating denotes resistance to solid particles, including dust, sand, and debris, while the second digit represents resistance to water ingress. For example, an IP67-rated bulb can withstand total dust exposure and temporary immersion in water without performance degradation.

Table 1: Common IP Ratings for High Lumens LED Headlight Bulbs

| IP Rating | Dust Protection | Water Protection | Typical Applications |

|---|---|---|---|

| IP65 | Dust tight | Water jets | General road use in moderate weather |

| IP66 | Dust tight | Powerful water jets | Off-road vehicles or high-pressure wash environments |

| IP67 | Dust tight | Temporary immersion | Vehicles exposed to rain, snow, or shallow flooding |

| IP68 | Dust tight | Continuous immersion | Specialized vehicles or extreme wet environments |

High Lumens LED Headlight Bulb performance is strongly correlated with its IP rating. Selecting the appropriate rating ensures that the lighting system maintains brightness, efficiency, and structural integrity even in challenging conditions.

Mechanisms of Water and Dust Ingress

Dust Ingress

Dust particles, even in microscopic forms, can settle on the LED lens, reflector, and heat sink surfaces. The presence of dust can cause several performance issues:

- Light Obstruction: Dust accumulation can scatter light, reducing effective lumens output and altering the beam pattern.

- Heat Retention: Dust on heat sinks diminishes thermal dissipation efficiency, causing elevated operating temperatures and accelerated LED degradation.

- Electrical Short Risk: Fine dust entering the internal circuitry can result in localized short circuits or corrosion of conductive paths.

Water Ingress

Water exposure introduces distinct challenges to High Lumens LED Headlight Bulbs:

- Corrosion of Electrical Components: Prolonged contact with moisture can corrode connectors, solder joints, and internal wiring.

- Short Circuits: Water within the LED driver or PCB assembly may trigger immediate failure or intermittent malfunction.

- Condensation on Lens Surface: Even minor water penetration can create fogging inside the lens, reducing optical clarity and altering beam intensity.

Testing and Certification Standards

To ensure High Lumens LED Headlight Bulb reliability under environmental stress, manufacturers conduct a series of standardized tests. Understanding these methods allows procurement professionals to evaluate product quality objectively.

- IP Testing: Bulbs are exposed to dust chambers and water jets or immersion according to IP standards. Performance is monitored to confirm protection level claims.

- Thermal Cycling with Moisture Exposure: Repeated heating and cooling cycles simulate real-world conditions, highlighting vulnerabilities in seals or adhesives.

- Vibration and Shock Tests: Environmental exposure combined with vibration ensures the bulb maintains water and dust resistance during operation on rough roads.

Table 2: Typical Water and Dust Resistance Test Protocols

| Test Type | Purpose | Typical Duration/Conditions |

|---|---|---|

| Dust Chamber Test | Evaluate particle ingress | 2–8 hours, fine particulate exposure |

| Water Jet Test | Confirm water resistance under pressure | 5–10 minutes, 12.5 L/min, 100 kPa pressure |

| Immersion Test | Test temporary or continuous water exposure | 30 minutes to 1 hour, 1 m depth |

| Thermal Cycling with Humidity | Assess seal integrity under condensation | -40°C to 85°C, 50–95% humidity, 10 cycles |

These test protocols are crucial benchmarks for High Lumens LED Headlight Bulb selection, especially for buyers targeting vehicles in regions with extreme weather conditions.

Practical Implications for Performance

Luminosity and Optical Performance

The optical efficiency of a High Lumens LED Headlight Bulb depends on the transparency and cleanliness of the lens and reflector. Water or dust ingress can result in reduced effective lumens output, creating uneven illumination and increasing the risk of glare or poor road visibility. Proper sealing ensures the light beam remains stable, uniform, and compliant with automotive standards.

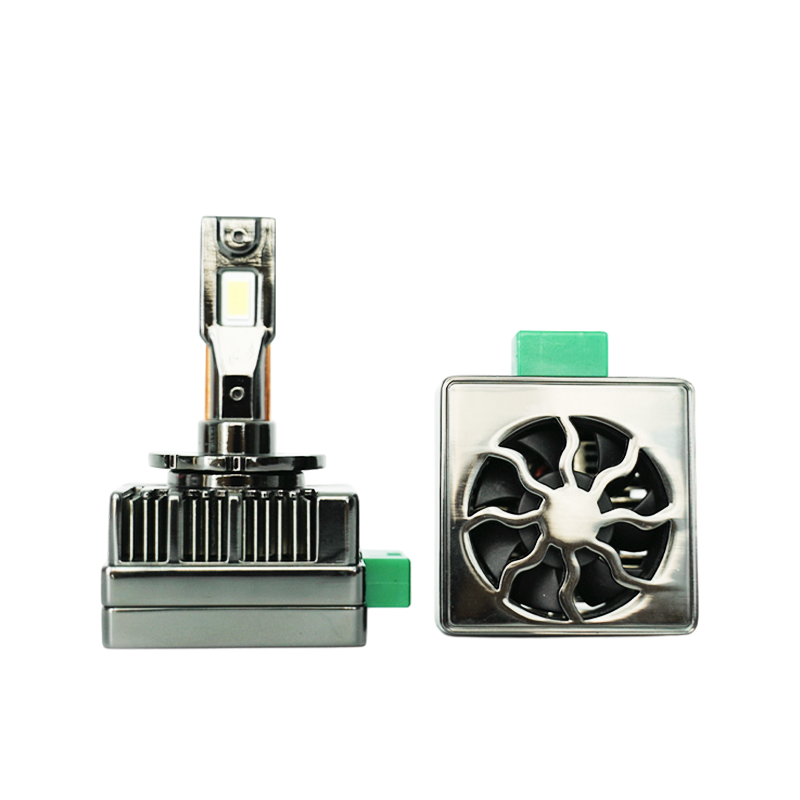

Thermal Management

LEDs generate heat during operation, and the efficiency of heat dissipation directly affects longevity. Dust accumulation or water penetration around heat sinks can significantly reduce thermal performance. Overheating accelerates LED chip degradation, driver malfunction, and mechanical failure of the housing. High Lumens LED Headlight Bulb designs often incorporate water- and dust-resistant enclosures with enhanced thermal pathways to mitigate this risk.

Reliability and Longevity

Water and dust resistance directly impacts the lifespan of High Lumens LED Headlight Bulbs. Bulbs with insufficient protection may exhibit early failure, flickering, or complete burnout under adverse conditions. Selecting products with proper IP ratings tailored to operational environments helps ensure consistent performance over time, reducing maintenance costs and downtime.

Considerations for Procurement

When sourcing High Lumens LED Headlight Bulbs, buyers should evaluate water and dust resistance alongside other key parameters such as brightness, beam pattern, and thermal management. Practical considerations include:

- Environmental Conditions: Vehicles operating in dusty deserts, rainy regions, or off-road terrain require higher IP ratings.

- Installation Orientation: Bulb orientation can influence susceptibility to water ingress and condensation.

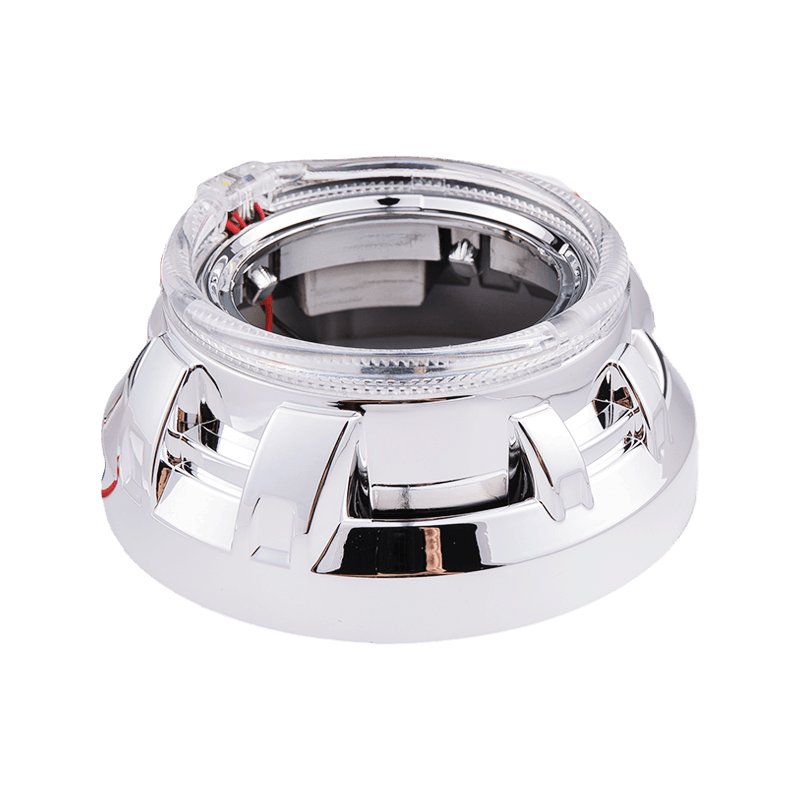

- Sealing Materials: Silicone gaskets, O-rings, and adhesive seals contribute significantly to long-term resistance.

- Maintenance Requirements: Even water- and dust-resistant bulbs may benefit from periodic inspection to remove accumulated debris and maintain optimal performance.

Innovations in Water and Dust Resistant Designs

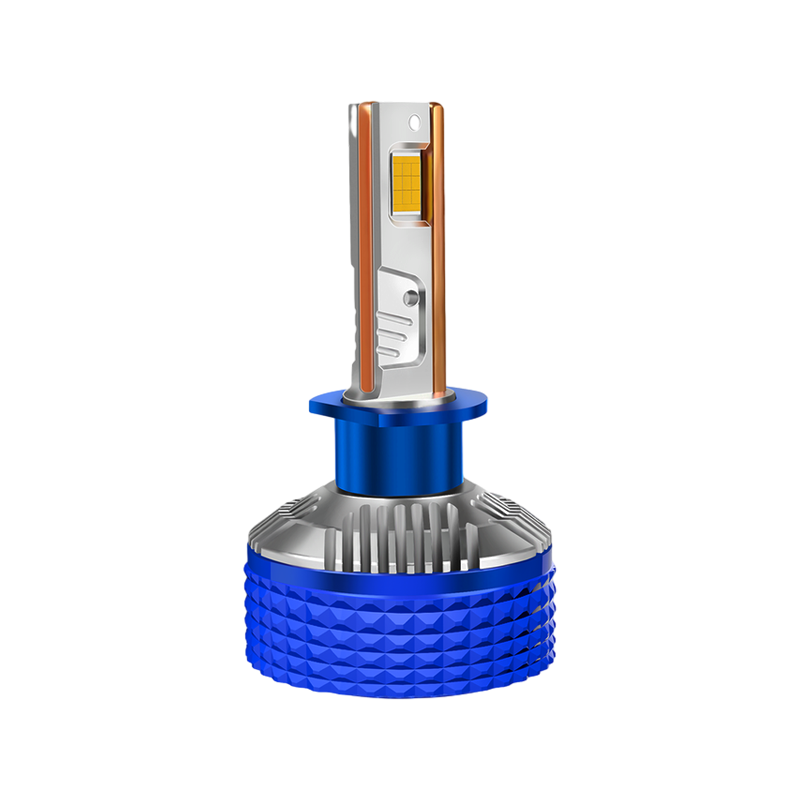

Recent advances in High Lumens LED Headlight Bulb technology focus on improving environmental resilience:

- Integrated Heat Sink and Housing Design: Seamless construction reduces potential ingress points.

- Hydrophobic Coatings: Lens and PCB surfaces repel water and prevent condensation formation.

- Enhanced Driver Encapsulation: LED drivers are fully potted in epoxy or silicone to maintain functionality under moisture exposure.

These innovations contribute to greater reliability, longer service life, and reduced maintenance frequency for high-performance automotive lighting systems.

Conclusion

Water and dust resistance plays a critical role in the performance, reliability, and longevity of High Lumens LED Headlight Bulbs. Buyers and technical professionals must consider IP ratings, environmental conditions, thermal management, and sealing technology when evaluating products. By prioritizing these factors, vehicles can maintain consistent brightness, optimal beam patterns, and long-term durability, even in challenging conditions. Investing in high-quality, environmentally resilient bulbs not only enhances driver safety but also reduces maintenance costs over the product lifecycle.

Frequently Asked Questions (FAQ)

Q1: What is the minimum IP rating recommended for daily driving conditions?

For most on-road vehicles, IP65 is sufficient to protect against dust and water jets encountered during rain or light splashing.

Q2: Can a High Lumens LED Headlight Bulb fail if water enters the lens?

Yes, water inside the lens can cause fogging, reduce light output, and potentially damage internal electronics. IP-rated bulbs are designed to prevent this.

Q3: How often should I inspect the bulb for dust accumulation?

Periodic inspection every 6–12 months is recommended, especially in off-road or dusty environments.

Q4: Does a higher IP rating guarantee longer bulb life?

While higher IP ratings enhance protection, overall lifespan also depends on thermal management, quality of LED chips, and driver circuitry.

Q5: Are hydrophobic coatings on lenses effective against condensation?

Yes, hydrophobic coatings can reduce internal fogging, improve light transmission, and maintain consistent beam performance.

References

- International Electrotechnical Commission (IEC), IEC 60529: Degrees of Protection Provided by Enclosures (IP Code), 2021.

- Automotive Lighting Technology Journal, “LED Headlight Environmental Testing and Performance,” Vol. 12, Issue 3, 2022.

- Journal of Automotive Engineering, “Durability and Reliability of LED Headlights under Dust and Moisture Exposure,” 2020.

English

English Español

Español عربى

عربى русский

русский