The mini bi led single light cup bifocal lens has become a critical component in modern vehicle lighting systems due to its precise beam focus and improved light distribution. For automotive enthusiasts, fleet operators, and maintenance professionals, ensuring the optimal performance and extended service life of these lenses is a priority. Proper maintenance not only preserves the visual performance of the lens but also minimizes operational risks and maintenance costs over time.

Understanding The Mini Bi LED Single Light Cup Bifocal Lens

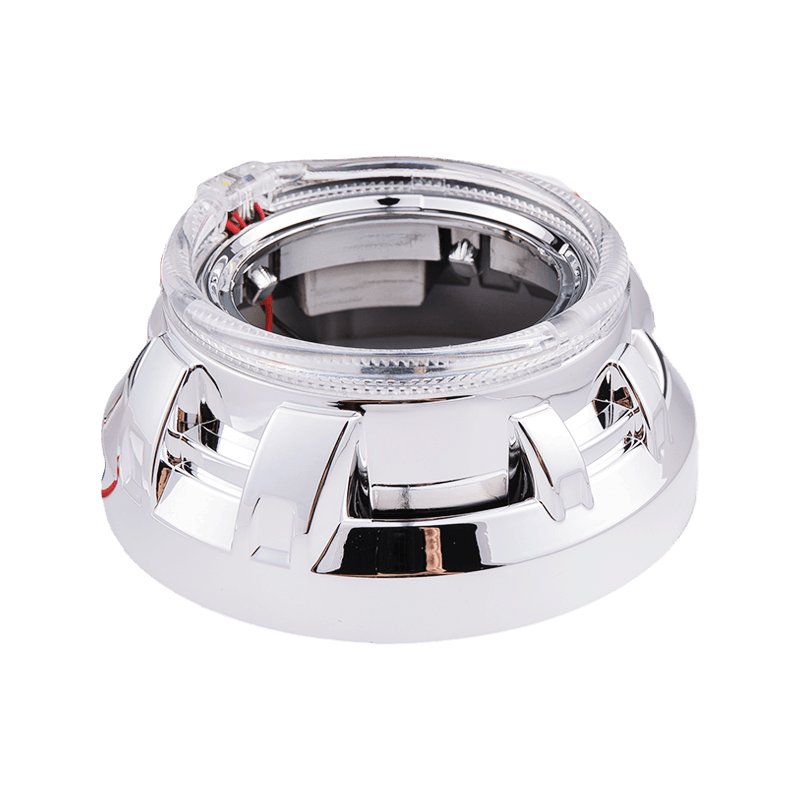

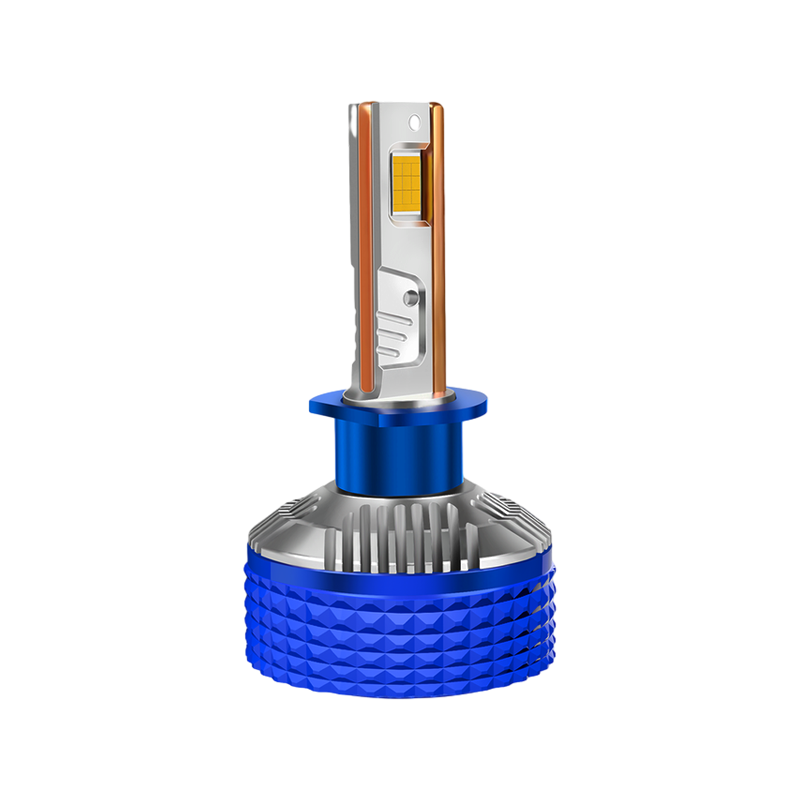

The mini bi led single light cup bifocal lens consists of an LED light source, a reflector cup, and a bifocal lens assembly. Its design ensures that both low beam and high beam lighting can be achieved from a single compact unit. Key attributes include:

- Precise light focus: Ensures clear illumination on the road without glare for oncoming traffic.

- Compact design: Facilitates integration in limited headlamp housings.

- Durable materials: Often constructed from high-temperature resistant plastics or glass with protective coatings.

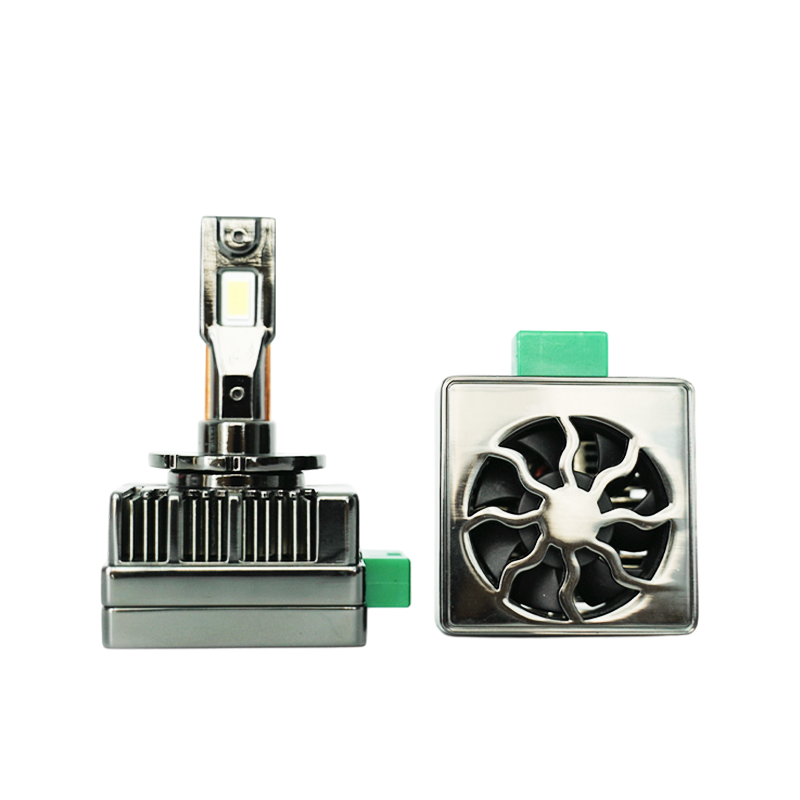

- Thermal management: Incorporates heat sinks or aluminum substrates to prevent LED overheating.

Understanding these components is essential, as each element can influence the maintenance requirements and overall longevity of the lens system.

Environmental Factors Affecting Lens Longevity

Environmental conditions play a crucial role in determining the lifespan of a mini bi led single light cup bifocal lens. Factors to consider include:

- Temperature fluctuations: Extreme heat or cold can degrade plastic or polycarbonate lenses, affecting optical clarity.

- Moisture exposure: Water ingress or condensation may compromise internal components, including LED chips and electrical contacts.

- Dust and debris: Road dust, sand, and other particles can cause surface scratches or reduce reflective efficiency.

- UV exposure: Prolonged exposure to sunlight can lead to yellowing or deterioration of polymer-based lens surfaces.

Table 1: Environmental Impact on Mini Bi LED Single Light Cup Bifocal Lens

| Environmental Factor | Potential Effect | Preventive Measure |

|---|---|---|

| High temperature | Lens warping, LED overheating | Use heat-resistant materials, ensure proper heat dissipation |

| Moisture / humidity | Condensation inside lens, electrical short | Seal lens units, use desiccant packets if needed |

| Dust / debris | Scratches, reduced optical efficiency | Regular cleaning with soft microfiber cloths |

| UV radiation | Yellowing of polymer surfaces | Apply UV-resistant coatings |

Understanding these factors helps in designing an effective maintenance schedule and preventing premature lens degradation.

Proper Handling And Installation

Correct handling and installation of the mini bi led single light cup bifocal lens are fundamental to extending its lifespan. Mishandling can result in irreversible damage to the lens or LED assembly.

- Handling precautions: Always hold the lens by its edges or housing. Avoid touching the optical surface directly, as oils and dirt from hands can reduce clarity.

- Installation alignment: Improper alignment of the lens may produce uneven light distribution, potentially causing safety issues. Use alignment tools to ensure accurate positioning.

- Connector care: Ensure that electrical connectors are free from corrosion and firmly seated to prevent intermittent operation.

Table 2: Handling And Installation Guidelines

| Action | Recommended Practice | Reason |

|---|---|---|

| Lens handling | Hold by housing edges only | Prevent surface contamination and scratches |

| Mounting alignment | Use optical alignment tools | Ensure proper beam pattern and road safety |

| Connector check | Inspect and secure all wiring | Maintain electrical reliability |

| Torque specification | Follow manufacturer guidelines | Prevent mechanical stress on lens assembly |

Correct installation reduces the risk of operational failure and minimizes the need for early replacements.

Cleaning And Surface Maintenance

Maintaining the optical clarity of mini bi led single light cup bifocal lens is critical. Accumulated dirt, grease, or oxidation can significantly impair performance.

- Surface cleaning: Use a soft microfiber cloth with mild soap and water. Avoid abrasive materials that may scratch the lens surface.

- Removal of stubborn contaminants: For insect residue, tar, or road grime, use automotive-grade lens cleaners compatible with polycarbonate or glass lenses.

- Coating preservation: Many lenses feature anti-reflective or protective coatings. Use cleaning solutions recommended by the lens manufacturer to prevent damage.

- Drying procedure: After cleaning, dry the lens with a soft lint-free cloth to prevent water spots.

Regular cleaning not only preserves light transmission efficiency but also ensures consistent beam focus for safety compliance.

Thermal Management Practices

Mini bi led single light cup bifocal lens relies heavily on proper heat dissipation. LED performance and lifespan are directly affected by temperature management.

- Heat sink inspection: Regularly inspect the heat sinks for dust or obstruction. Blocked airflow can raise the operating temperature, accelerating LED degradation.

- Ventilation pathways: Ensure ventilation slots or channels are unobstructed. Proper airflow helps maintain optimal thermal conditions.

- Ambient temperature monitoring: Operating the lens at temperatures beyond recommended limits can shorten the LED lifespan.

Implementing these measures ensures sustained brightness and prevents thermal-related failures.

Preventive Measures And Routine Checks

Preventive maintenance extends the operational life of mini bi led single light cup bifocal lens. Key practices include:

- Regular inspection: Check for signs of lens yellowing, surface scratches, or condensation.

- Electrical testing: Periodically verify voltage and current levels to ensure LEDs are not overdriven.

- Sealing integrity: Inspect seals and gaskets to prevent moisture ingress.

- Replacement of worn components: If any internal reflector or lens element shows wear, replace promptly to maintain optical performance.

Integrating these checks into a maintenance schedule minimizes downtime and enhances reliability.

Maintenance Tools And Accessories

Using appropriate tools enhances maintenance efficiency and reduces risk of damage. Common tools include:

- Soft microfiber cleaning cloths

- Automotive-grade lens cleaning solutions

- Non-abrasive brushes for heat sinks

- Alignment tools for beam adjustment

- Compressed air for dust removal

Proper tool selection is essential to avoid scratching or compromising the optical surfaces.

Industry Considerations For Buyers

For professionals procuring mini bi led single light cup bifocal lens, understanding the maintenance requirements is crucial. Buyers should evaluate:

- Compatibility with existing headlamp assemblies

- Availability of replacement parts and accessories

- Recommended cleaning and maintenance procedures

- Environmental resistance and material quality

This evaluation ensures long-term performance and supports cost-effective operation.

Conclusion

Maintaining mini bi led single light cup bifocal lens for longer life involves careful handling, regular cleaning, thermal management, and preventive inspections. By adhering to these practices, users can ensure optimal performance, consistent beam quality, and extended service life. A structured maintenance plan, combined with industry-standard procedures and proper tools, is essential for preserving the integrity and functionality of these advanced lens systems.

FAQ

Q1: How often should I clean my mini bi led single light cup bifocal lens?

A1: Cleaning should be performed at least every 2-3 months, or more frequently in dusty or harsh environments.

Q2: Can I use household cleaning chemicals on the lens?

A2: No, only automotive-grade lens cleaners are recommended to avoid damaging coatings or optical clarity.

Q3: What is the main cause of lens yellowing?

A3: Yellowing is typically caused by prolonged UV exposure or chemical interaction with low-quality cleaning agents.

Q4: How do I check if the lens is properly aligned?

A4: Use beam alignment tools to ensure that the light focus meets road safety standards.

Q5: Can minor scratches be polished out?

A5: Yes, using specialized polishing kits designed for polycarbonate or glass lenses can reduce surface scratches, but care must be taken to preserve coatings.

References

- Automotive Lighting Technology Guide, International Automotive Engineers Association, 2022

- LED Lighting Maintenance Handbook, Advanced Vehicle Systems, 2021

- Optical Lens Design and Maintenance Practices, Journal of Vehicle Electronics, 2020

English

English Español

Español عربى

عربى русский

русский