In the field of automotive lighting, waterproof IP68 LED headlight bulbs are favored by more and more users due to their excellent waterproof and dustproof performance and high efficiency and energy saving. However, to give full play to their performance advantages, correct installation is essential.

1. Preparation before installation

(I) Confirmation of product specifications

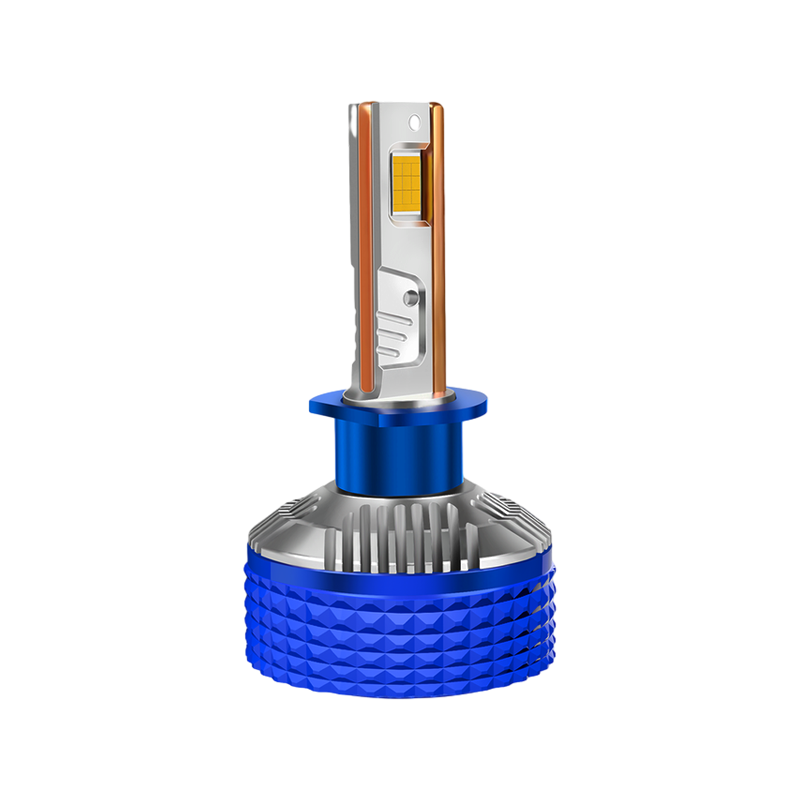

Before installing waterproof IP68 LED headlight bulbs, you must first confirm whether the product specifications are suitable for the vehicle. There are differences in the headlight interface and voltage requirements of different models. If the specifications do not match, not only will it not be installed normally, but it may also damage the bulb or the vehicle circuit system. You need to carefully check the interface type of the bulb. Common ones include H7, H11, 9005, 9006, etc., to ensure that it is completely consistent with the vehicle headlight base interface. At the same time, clarify the power supply voltage of the vehicle. The general working voltage of the car is 12V or 24V, and the rated voltage of the LED headlight bulb must be consistent with it to avoid the bulb failing to light up or premature damage due to voltage mismatch.

(II) Product quality inspection

After receiving the waterproof IP68 LED headlight bulb, you need to conduct a comprehensive inspection of its appearance and performance. In terms of appearance, carefully check whether there are cracks, damage, deformation, etc. on the surface of the bulb, especially the sealing part, to ensure that there are no gaps or defects, as these may affect the waterproof performance of the bulb. At the same time, check whether the connection wires of the bulb are intact, whether there are any damaged or exposed wires, to prevent short circuits and other problems during installation and use. In terms of performance inspection, you can use professional testing equipment to perform a simple power-on test on the bulb in a safe environment to check whether the bulb can light up normally, whether the light is uniform, and whether there are any abnormal phenomena such as flickering.

(III) Tool preparation

Some specific tools are required to install waterproof IP68 LED headlight bulbs. Necessary tools include screwdrivers for removing and installing the fixing screws of the headlight assembly; gloves. Wearing gloves during operation can prevent grease and stains on the hands from adhering to the surface of the bulb, affecting heat dissipation and service life, and also protect the hands from burns from high-temperature components; protective glasses to prevent accidental splashing of parts during removal or installation, causing eye damage. In addition, you can also prepare some auxiliary tools, such as flashlights, which are convenient for seeing the installation site in low light conditions; insulating tape, which is used to insulate the exposed wires to ensure circuit safety.

(IV) Vehicle power off and protection

To ensure personal safety and the safety of the vehicle circuit system during the installation process, the vehicle must be powered off before installation. Generally speaking, disconnecting the negative pole of the vehicle's battery can cut off the power supply. At the same time, the surrounding area of the vehicle is protected, and a protective mat can be laid on the front of the vehicle to prevent tools or parts from falling during the installation process and scratching the vehicle paint. For parts around the headlight assembly, such as bumpers, decorative panels, etc., appropriate protective measures must also be taken to avoid damage during removal and installation.

2. Installation process

(I) Headlight assembly removal

The removal methods of headlight assemblies for different models are slightly different, but the overall process is similar. First, use a screwdriver to remove the fixing screws of the headlight assembly, which are usually distributed around and at the bottom of the headlight assembly. When removing the screws, be careful to keep the screws to avoid losing them. After the screws are removed, carefully remove the headlight assembly from the vehicle. Be careful not to pull the wiring harness connected to the headlight assembly to prevent damage to the wiring harness. If there is a clip or other fixing device between the headlight assembly and the vehicle body, it needs to be loosened in the correct way to ensure that the headlight assembly can be removed smoothly.

(II) Removal of the old bulb

After removing the headlight assembly, find the location of the old bulb. Generally speaking, the old bulb is fixed in the headlight assembly by clips or tightening. For bulbs fixed by clips, gently press the clip and pull it outward to remove the old bulb; for bulbs fixed by tightening, rotate the bulb in the correct direction of rotation (usually counterclockwise) to unscrew it. When removing the old bulb, pay attention to the force to avoid damaging the internal structure of the headlight assembly.

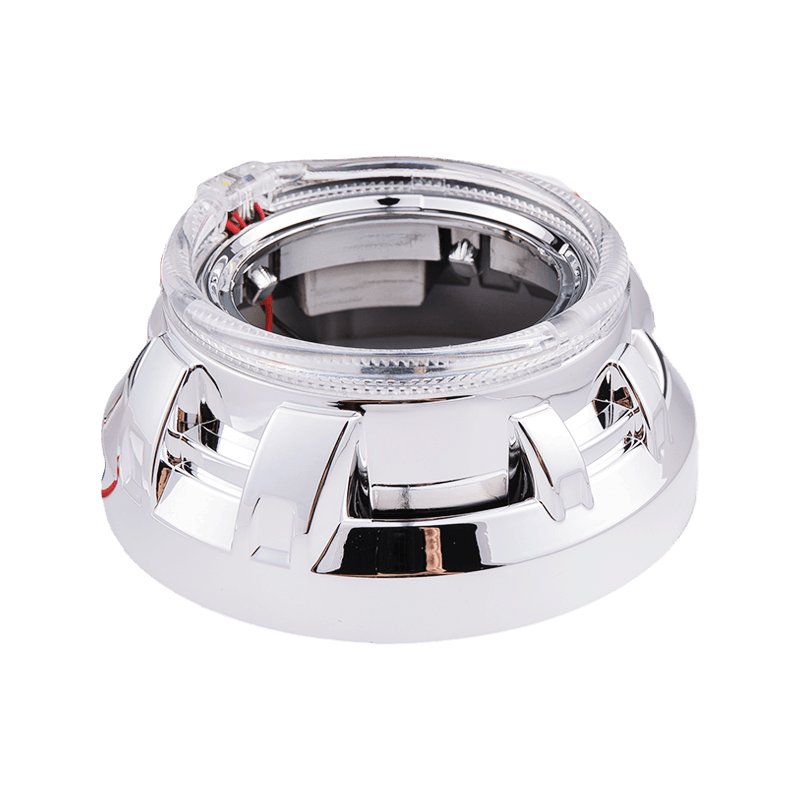

(III) Installation of waterproof IP68 LED headlight bulbs

Align the waterproof IP68 LED headlight bulb with the installation interface of the headlight assembly and ensure that the interface is in the correct direction. If the bulb uses a plug-in interface, insert the bulb smoothly into the interface until you hear a "click" sound, indicating that the bulb has been installed in place; if it is a screw-on interface, slowly rotate the bulb in a clockwise direction until it is tightened. During the installation process, make sure that the bulb is tightly connected to the interface to avoid looseness, otherwise it may affect the waterproof performance and lighting effect of the bulb. At the same time, be careful not to use excessive force to prevent damage to the bulb or interface.

(IV) Wiring harness connection

After the bulb is installed, connect the wiring harness. Correctly connect the bulb's connecting wire to the vehicle's headlight harness to ensure that the plug and socket are fully matched and the connection is firm. For some waterproof IP68 LED headlight bulbs with decoders or driver modules, correctly connect the decoder or driver module according to the requirements of the manual and fix it in a suitable position to avoid loosening or damage to the wiring harness due to shaking during vehicle driving. After connecting the wiring harness, wrap the connection part of the wiring harness with insulating tape to prevent moisture and dust from entering and ensure the reliability of the circuit connection.

(V) Reset the headlight assembly

After completing the installation of the bulb and wiring harness, reinstall the headlight assembly back to the original position of the vehicle. Fix the headlight assembly to the vehicle in the reverse order of disassembly and tighten the fixing screws. When tightening the screws, tighten them in the order of diagonal lines to ensure that the headlight assembly is firmly installed and evenly stressed. After installation, check whether the gap between the headlight assembly and the vehicle body is uniform and whether there is any misalignment. If there is any problem, make adjustments in time.

3. Post-installation inspection

(I) Functional inspection

After installation, restore the vehicle power supply, start the vehicle, turn on the headlight switch, and check whether the waterproof IP68 LED headlight bulb can be lit normally. Test the low beam, high beam, turn signal and other functions separately to check whether the light effect of the bulb is normal, whether there is flickering, uneven brightness, etc. At the same time, observe whether there is a light fault alarm prompt on the vehicle dashboard. If an alarm occurs, turn off the headlight immediately, check whether there is any problem with the installation of the bulb and the connection of the wiring harness, and repair it in time.

(II) Waterproof performance test

Waterproof performance is an important indicator of waterproof IP68 LED headlight bulbs. After installation, its waterproof performance needs to be tested. You can use the water spray test method, use a water sprayer or a water pipe, and spray water on the headlight with a uniform water flow at a certain distance (such as 30-50 cm) to simulate the environment of a vehicle driving in rainy days. The water spraying time lasts for 3-5 minutes, and then turn on the headlight assembly to check whether there are water stains or water ingress on the bulb and inside. If water is found to have entered, it means that there is a problem with the waterproof seal. It is necessary to recheck the installation and sealing parts of the bulb to ensure that the seal is good.

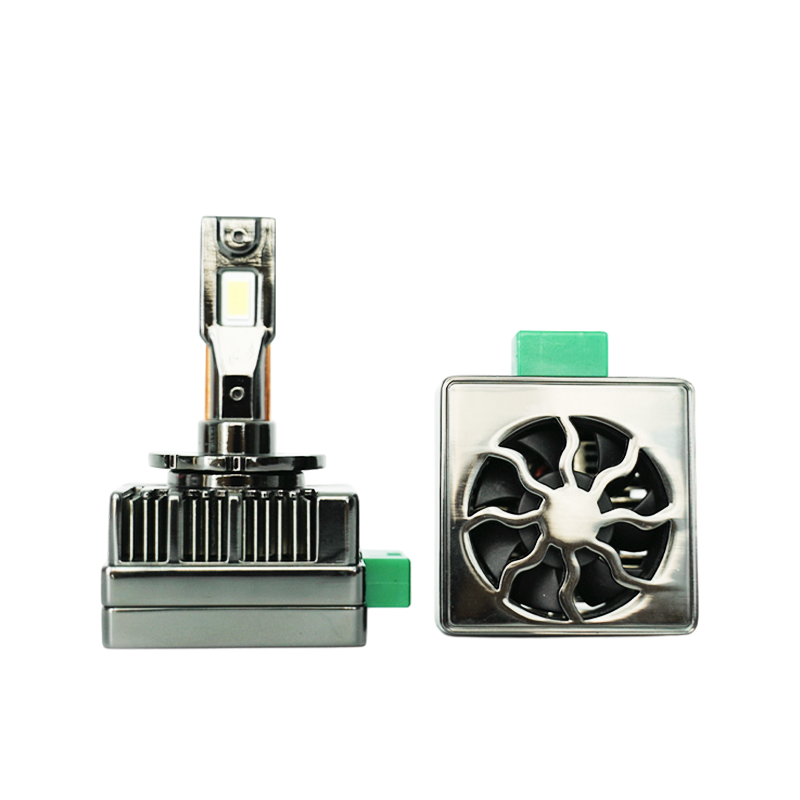

(III) Heat dissipation inspection

The heat dissipation performance of LED headlight bulbs directly affects its service life and performance. After the bulb is lit for a period of time (such as 10-15 minutes), turn off the headlight, touch the heat dissipation part of the bulb with your hand (be careful to avoid burns), and feel its temperature change. Under normal circumstances, the heat dissipation part of the bulb will have a certain temperature increase, but it should not overheat. If the temperature feels too high, it may be that the cooling device is improperly installed or the cooling environment is not good. You need to check whether the cooling fan of the bulb is operating normally, whether the heat sink is installed in place, and the ventilation inside the headlight assembly to ensure that the bulb can dissipate heat well.

English

English Español

Español عربى

عربى русский

русский